Product Category

VF360 Vertical Packaging Machine

Product Advantages The cross-seal structure is equipped with a new type of anti-folding device,which is easy to adjust and has stable performance. Vacuum film pulling, servo film pulling system with planetary reducer, moreaccurate and stable operation. Automatic deviation correction system, tracking and alignment is accurate andconvenient, adapting to the needs of different customers and developing abroader market. Improved formers, lightweight structural design, more convenient to install, butalso the use of lever locker, installation of tight, will not automatically loose.

MOREVarious Customized Working Platform

1. Stainless steel/aluminum surface, aluminum floor and steps, stainless steel handrails/ support legs. 2. Strong and generous, durable. 3. The platform is beautiful, anti- skid and safe. 4. Simple structure, easy to maintain. 5. Small energy consumption and low use cost. 6. Low noise, suitable for quieter working environment. 7. The conveying is stable, the material and the conveyor belt have no relative movement, can avoid the damage to the conveying material. 8. Oil resistance, corrosion resistance, anti- static. 9. Impact resistance and shock absorption.

MOREPACW-210 Digital Automatic Checkweigher

This product is suitable for testing the weight of individual products. It is widely used in many industries such as electronics, pharmaceuticals, food, beverages, health products, daily chemicals, light industry, agricultural and sideline products. Such as food industry conditioning products, candy, cakes, ham, instant noodles, frozen foods, food additives, pigments, modifiers, preservatives.

MOREConveyor type high-precision metal detector, German technology, high detection accuracy and excellent performance. It is suitable for the detection of metal impurities in products in the food, pharmaceutical, chemical and other industries, and the detection of bulk materials and packaged products. Includes a wide range of conveyor systems and efficient rejects to meet a variety of application needs.

MOREVegetable Packing Machine With Weighing And Labeling Fuctions

1、Adopt the fibre optical sensor to detect the length of pr oduct automatically, so the product length is not required; 2、Detect the products automatically,if no product go into the film, the machine will stop, no empty bag and no cutting the products; 3、 Servo motor controls the horizontal sealing device and t he cutter. Simple operation and convenient maintenance; 4、More quiet working, more stable running, more delicate construction; 5、Adopt imports electric appliance,touched screen with e asy setting up parameter and fault self-diagnosis function, good understanding for fault on the screen; 6、High sensitive sensor to track the eye mark, so the positic on of sealing and cutting will be more accuracy; 7、Independent PID controls the temperature so various fil m materials can be used; 8、Fixed position and machine stops, no waste the film and no stick on the cutter; 9、Simple driving system,reliable working, convenient main tenance.

MORE1、Suitable for sticky products weighing,such as kimchi,fresh meat,friend rice,etc. 2、IP65 waterproof,use water cleaning directly,save time while cleaning; 3、Modular control system,more stability and lower maintenance cost; 4、Production records can be checked at anytime or download to PC; 5、Load cell or photo sensor checking to satisfy different requirements; 6、Scraper gate design make sure products are disable to be stuck on hoppers; 7、Designed screw-type linear pan to feed product stable and continuous; 8、Refer to product features,select automatic or manual feeding amplitude; 9、Food contact parts disassembling without tools ,easier to clean; 10、Multi-language touch screen for various clients,English,French,Spanish,etc; 11、PC monitor production status,clean on production progress(Option).

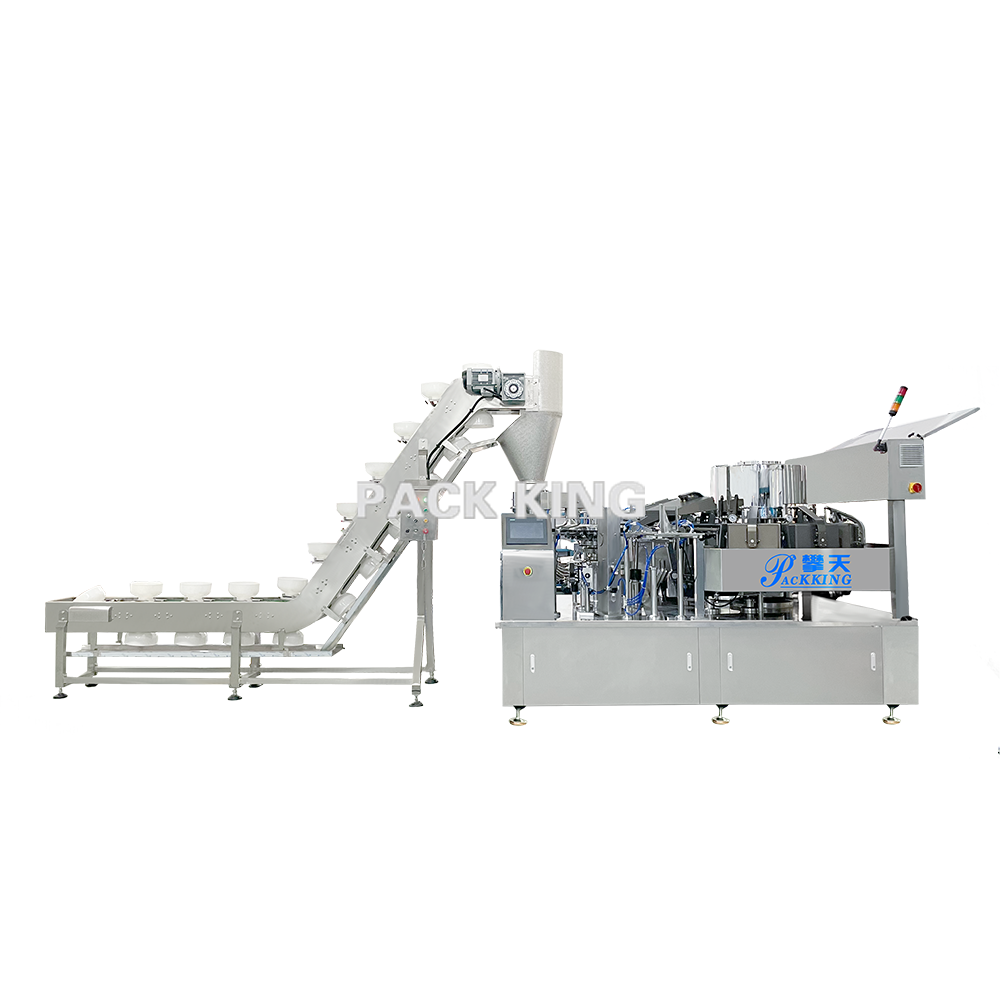

MOREPackaging system for laundry pods with high weight precision

The packaging production line consisting of a Z-type conveyor ,platform, a multi-head weigher, a bag-feeding packaging machine, finished good conveyor ,and a check weigher. Granular (nuts, candies, etc.), block-shaped (puffed food, quick-frozen meat pieces, etc.), irregular (fragile items like biscuits, potato chips, etc.).Materials are lifted to the platform via Z-type conveyor belt and accurately weighed by multi-head combination weigher; Premade bag packaging machine automatically completes bag taking, filling and sealing; Check weigher rejects unqualified products. Metering accuracy reaches ±0.1-1.5g, with firm and beautiful sealing, which can protect the integrity of fragile products. Full automation improves efficiency; Z-type design saves space; adapts to products of multiple specifications; reduces pollution and labor costs.

MOREA packaging system for particulate products in workshops withlimited height

This is a complete packing system for packaging soybeans in back-seal bags. Due to height restrictions in the customer's workshop, we developed this solution based on the specific needs. An independent vibrating machine with a large-capacity silo stores and supplies the material. A small z-bucket elevator then feeds the material to a multihead weigher. After weighing, the multihead weigher unloads the material onto a bowl conveyor for transport to vertical packaging machine. After packaging, a takeaway conveyor unloads the finished product, which is collected by a rotary table and then manually packed into cartons or transfer boxes. This system is commonly used for packaging dry granular materials in workshops with limited height, making full use of the plant space.

MORESolid + liquid vacuum packaging system for large bulkmaterials

The "bowl conveyor + vacuum packaging machine" is a highly efficient solution for industrialized food production, particularly suitable for products requiring bowl-shaped packaging, such as ready meals, cooked foods, and pickled vegetables. Combining automated feeding with vacuum sealing, this system achieves packaging that maintains freshness, prevents leakage, and maintains a good appearance, while also meeting production requirements for high production capacity, low labor costs, and consistent quality. It is a core equipment combination for food companies to enhance their scale competitiveness.

MOREAutomated packaging system for solid particles

Automated Packaging Line for Dried Blueberries Our advanced packaging system efficiently handles dried blueberries with seamless automation. It begins with the Z-type elevator, which gently transports the material to the 10-head multihead weigher for precise weighing. The support platform ensures smooth transitions between stages. The pre-made bag packaging machine then fills and seals the bags accurately. This fully automated line ensures not only visually appealing and secure packaging but also significantly reduces labor costs. The entire process, from conveying and weighing to packaging, requires minimal human intervention, guaranteeing both efficiency and consistency.

MOREMultihead Weigher With Rotary Packer On Dried Fruits

The packaging production line consisting of a Z-type conveyor ,platform, a multi-head weigher, a bag-feeding packaging machine, finished good conveyor ,and a check weigher. Granular (nuts, candies, etc.), block-shaped (puffed food, quick-frozen meat pieces, etc.), irregular (fragile items like biscuits, potato chips, etc.).Materials are lifted to the platform via Z-type conveyor belt and accurately weighed by multi-head combination weigher; Premade bag packaging machine automatically completes bag taking, filling and sealing; Check weigher rejects unqualified products. Metering accuracy reaches ±0.1-1.5g, with firm and beautiful sealing, which can protect the integrity of fragile products. Full automation improves efficiency; Z-type design saves space; adapts to products of multiple specifications; reduces pollution and labor costs.

MOREAuger Filler With Rotary Packer On Milk Powder

This system is commonly used for packaging dry granular materials in workshops with limited height, making full use of the plant space. This is a system for powder packaging. The powder is first agitated from the screw conveyor to the auger filler. The auger filler is a device used for powder metering, and its function is to do quantitative feeding. After the material is down, it enters the bag feeding machine for packaging. The whole system is simple in design and does not require excessive equipment for production, helping customers save money and space.

MORE