Product Category

Multihead Weigher With Rotary Packer On Confectionery

More and more confectionery processors focus on its package way in order to rasie more market for themselves, doybag will be a new trend, which attract more customers and they are willing to pay more on it! Rotary packer will be the best choice to complete it, perfect match with multihead weigher to create good performance! Except that, we can set integrated conveyor, platform, throat metal detector, check weigher with rotary table to complete fully automatic packaging line for our customers!

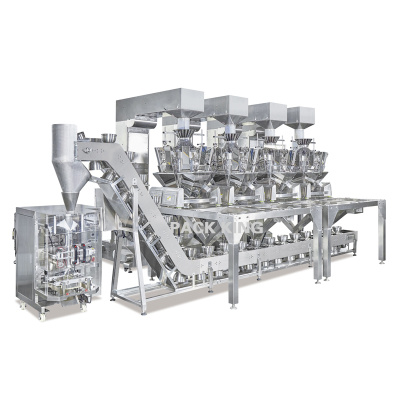

MOREMultihead Weigher With Twin Baggers On Snacks

Snacks will be treated as one of main recipe nowaday! Processor not just focus on its taste quality, but also its production capacity, especially busy season, they are willing to pay more attention on its packaging performance improvement! Higher speed will be a key point for them and we also have higher configurations to meet their demands, such as 24 head weigher working with twin baggers design. Except that, both special made platform with conveyor are necessary to complete the whole line on snacks!

MOREVolumetric With Packing Machine On Beans

Different from traditional powder packaging, this system uses a volumetric cup for metering instead of auger filler. This simple design can speed up the feeding speed and improve the packaging speed of the system. The lifting part configures a single bucket elevator to directly lift 40-60L powder into the storage hopper of volumetric cups. Volumetric cups automatically rotate and will combine to the set weight and then unloaded to the packaging machine. This type of packaging system is widely used in various powder packaging, such as coffee powder, flour, seasoning powder, etc.

MOREScrew Conveyor With Packing Machine On Seasoning

This is a system for powder products from packaging to weight inspection. The powder is first agitated from the screw conveyor to the auger filler. The auger filler is a device used for powder metering, and its function is to do quantitative feeding. After the material is down, it enters the vertical packing machine for packaging. After the packaging is completed, the output conveyor is automatically transported to the check weigher for weight detection. This is the machine which is uesd to detect whether the weight of a single product is consistent with the set target, and the sorting device will automatically eliminate products that do not conform the standard. Products that meet the requirements will be conveyed to the turn table. In this way, the whole packaging system is finished. The whole set is linkage control, automatic feeding, stop working without materials.

MOREBowl Conveyor With Packing Machine On Mixture Breakfast

Mixed material packaging system. When a bag requires the mixing of several materials, such as mixed nuts, candies, etc. Different packaging machines are configured according to the type of material and weighing dose. The bowl elevator receives the material of each multihead weigher in sequence, until it reaches the packaging machine directly at the end of the package.

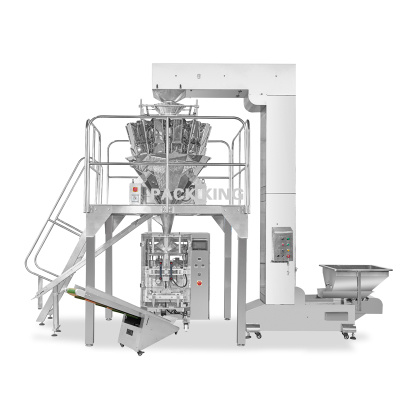

MOREIntegrated Z-shape Conveyor With Multihead Weigher On Biscuits

Integrated Z-shape conveyor is more suitable for the situation where the factory space is limited, accurately weighed by a multi-head weigher, equipped with parcel delivery machine to deliver food desiccant, follow the material into the vertical packaging machine. Perfect match for the biscuits and other snack.

MORE1、Low power consumption, easy to operate. 2、Easy installation, large throughput. 3、The use of speed regulating motor, by changing the belt speed to adjust the ore. 4、Low noise and low cost. 5、Simple structure, convenient maintenance. 6、Beautiful appearance, standardized parts. 7、Can be customized according to customer needs.

MOREPack King Design Spiral Screw Feeder Suitable For Powder Horizontal Screw Feeder

1、Simple structure, easy to operate. 2、Small size, good sealing effect, can play a dustproof role. 3、Can be customized according to customer requirements. 4、The vibration and vibration range of the material box can be adjusted, the material box is designed independently, easy to take off. 5、304 stainless steel sanitary buildings and food grade plastics. 6、Labor-saving conveyor, allowing a large number of material movement. 7、Reliable work, low energy consumption. Corrosion and wear resistance. 8、Requires low maintenance, easy to clean.

MORECumtomized Independent Vibrating Feeder For Food Soybean Rice Tea

1. The bin is welded with 304 stainless steel material and can be disassembled. 2. The amplitude can be adjusted at any time to control the flow, convenient and stable. 3. Electromagnet type mechanical vibration, simple structure, convenient installation and maintenance. 4. Feeder (electromagnetic vibration feeder) vibration is stable and strong, so that the product transmission is uniform. 5. Reliable work and long life. 6. High quality and reliable work. 7. Light weight and small size. 8. Low noise, less power consumption, no impact material phenomenon, machine environmental protection. 9. Low maintenance and easy maintenance. 10. High efficiency and large feeding capacity. 11. Dust pollution can be prevented when enclosed structure fuselage is used. 12. Can be customized according to customer needs.

MOREOnline Sale Vertical Supporting Working Platforms For Whole Conveying Line Packing System

1. Stainless steel/aluminum surface, aluminum floor and steps, stainless steel handrails/ support legs. 2. Strong and generous, durable. 3. The platform is beautiful, anti- skid and safe. 4. Simple structure, easy to maintain. 5. Small energy consumption and low use cost. 6. Low noise, suitable for quieter working environment. 7. The conveying is stable, the material and the conveyor belt have no relative movement, can avoid the damage to the conveying material. 8. Oil resistance, corrosion resistance, anti- static. 9. Impact resistance and shock absorption.

MOREMetal impurities and metal foreign bodies in food, testing food, bread, steamed buns, steamed buns, dumplings, biscuits and other products, as well as testing products or raw materials in pharmaceuticals, toys, clothing, footwear, chemicals, leather, knitting and other industries mixed in the production process Metal impurities. Such as: iron and non-ferromagnetic metal items (non-ferrous metals such as iron, copper, aluminum, stainless steel, etc. can be detected), improve product safety factor, and improve product quality.

MOREPACW-300 Digital Automatic Checkweigher

This product is suitable for testing the weight of individual products. It is widely used in many industries such as electronics, pharmaceuticals, food, beverages, health products, daily chemicals, light industry, agricultural and sideline products. Such as food industry conditioning products, candy, cakes, ham, instant noodles, frozen foods, food additives, pigments, modifiers, preservatives.

MORE