Product Category

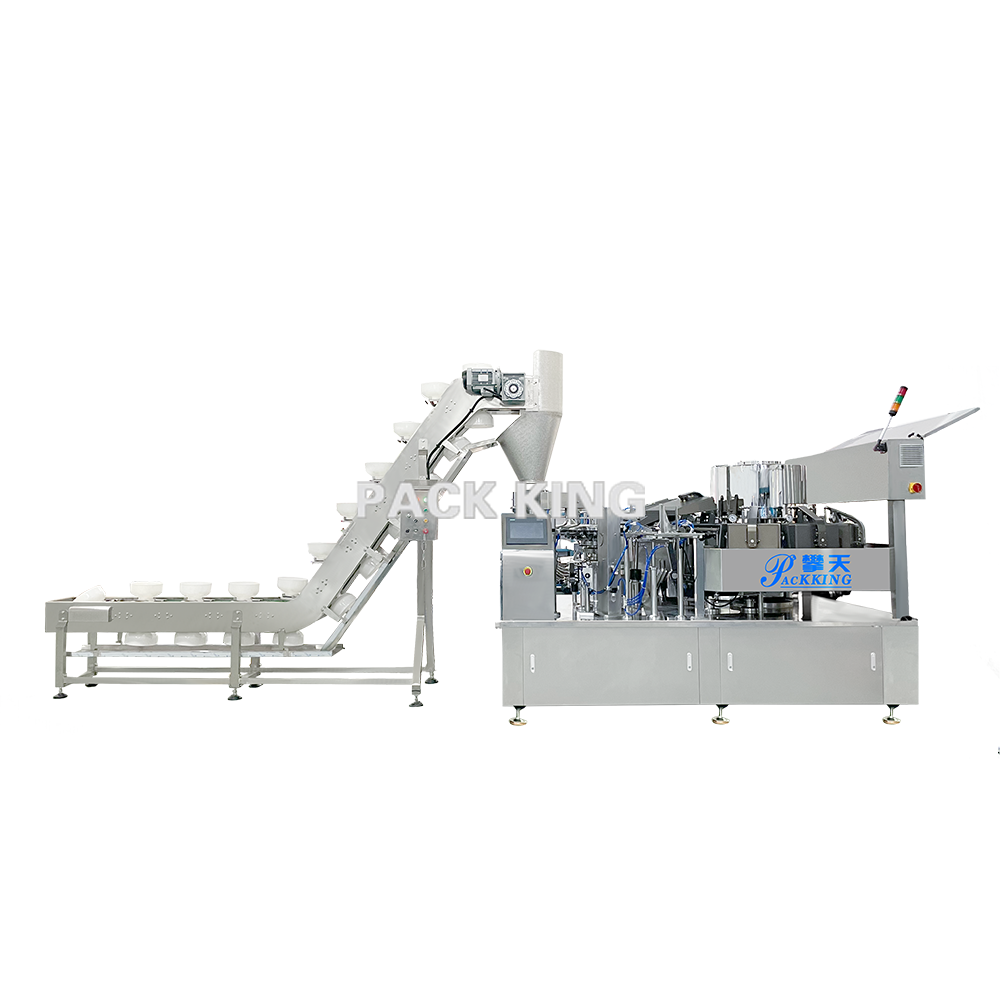

Packaging system for laundry pods with high weight precision

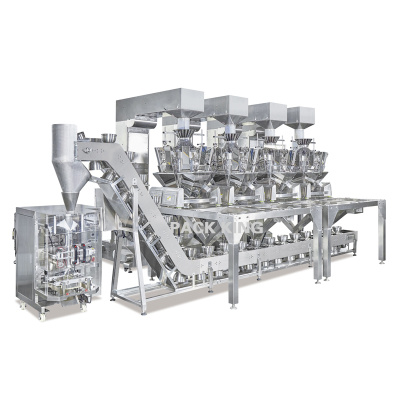

The packaging production line consisting of a Z-type conveyor ,platform, a multi-head weigher, a bag-feeding packaging machine, finished good conveyor ,and a check weigher. Granular (nuts, candies, etc.), block-shaped (puffed food, quick-frozen meat pieces, etc.), irregular (fragile items like biscuits, potato chips, etc.).Materials are lifted to the platform via Z-type conveyor belt and accurately weighed by multi-head combination weigher; Premade bag packaging machine automatically completes bag taking, filling and sealing; Check weigher rejects unqualified products. Metering accuracy reaches ±0.1-1.5g, with firm and beautiful sealing, which can protect the integrity of fragile products. Full automation improves efficiency; Z-type design saves space; adapts to products of multiple specifications; reduces pollution and labor costs.

MOREA packaging system for particulate products in workshops withlimited height

This is a complete packing system for packaging soybeans in back-seal bags. Due to height restrictions in the customer's workshop, we developed this solution based on the specific needs. An independent vibrating machine with a large-capacity silo stores and supplies the material. A small z-bucket elevator then feeds the material to a multihead weigher. After weighing, the multihead weigher unloads the material onto a bowl conveyor for transport to vertical packaging machine. After packaging, a takeaway conveyor unloads the finished product, which is collected by a rotary table and then manually packed into cartons or transfer boxes. This system is commonly used for packaging dry granular materials in workshops with limited height, making full use of the plant space.

MORESolid + liquid vacuum packaging system for large bulkmaterials

The "bowl conveyor + vacuum packaging machine" is a highly efficient solution for industrialized food production, particularly suitable for products requiring bowl-shaped packaging, such as ready meals, cooked foods, and pickled vegetables. Combining automated feeding with vacuum sealing, this system achieves packaging that maintains freshness, prevents leakage, and maintains a good appearance, while also meeting production requirements for high production capacity, low labor costs, and consistent quality. It is a core equipment combination for food companies to enhance their scale competitiveness.

MOREAutomated packaging system for solid particles

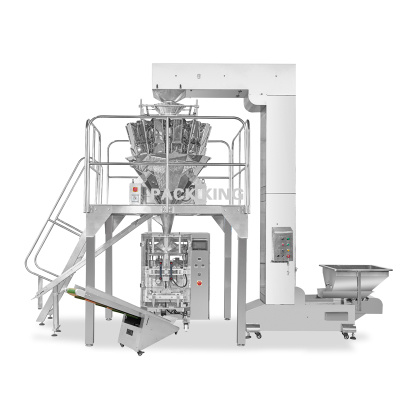

Automated Packaging Line for Dried Blueberries Our advanced packaging system efficiently handles dried blueberries with seamless automation. It begins with the Z-type elevator, which gently transports the material to the 10-head multihead weigher for precise weighing. The support platform ensures smooth transitions between stages. The pre-made bag packaging machine then fills and seals the bags accurately. This fully automated line ensures not only visually appealing and secure packaging but also significantly reduces labor costs. The entire process, from conveying and weighing to packaging, requires minimal human intervention, guaranteeing both efficiency and consistency.

MOREMultihead Weigher With Rotary Packer On Dried Fruits

The packaging production line consisting of a Z-type conveyor ,platform, a multi-head weigher, a bag-feeding packaging machine, finished good conveyor ,and a check weigher. Granular (nuts, candies, etc.), block-shaped (puffed food, quick-frozen meat pieces, etc.), irregular (fragile items like biscuits, potato chips, etc.).Materials are lifted to the platform via Z-type conveyor belt and accurately weighed by multi-head combination weigher; Premade bag packaging machine automatically completes bag taking, filling and sealing; Check weigher rejects unqualified products. Metering accuracy reaches ±0.1-1.5g, with firm and beautiful sealing, which can protect the integrity of fragile products. Full automation improves efficiency; Z-type design saves space; adapts to products of multiple specifications; reduces pollution and labor costs.

MOREAuger Filler With Rotary Packer On Milk Powder

This system is commonly used for packaging dry granular materials in workshops with limited height, making full use of the plant space. This is a system for powder packaging. The powder is first agitated from the screw conveyor to the auger filler. The auger filler is a device used for powder metering, and its function is to do quantitative feeding. After the material is down, it enters the bag feeding machine for packaging. The whole system is simple in design and does not require excessive equipment for production, helping customers save money and space.

MOREMultihead Weigher With Rotary Packer On Confectionery

More and more confectionery processors focus on its package way in order to rasie more market for themselves, doybag will be a new trend, which attract more customers and they are willing to pay more on it! Rotary packer will be the best choice to complete it, perfect match with multihead weigher to create good performance! Except that, we can set integrated conveyor, platform, throat metal detector, check weigher with rotary table to complete fully automatic packaging line for our customers!

MOREMultihead Weigher With Twin Baggers On Snacks

Snacks will be treated as one of main recipe nowaday! Processor not just focus on its taste quality, but also its production capacity, especially busy season, they are willing to pay more attention on its packaging performance improvement! Higher speed will be a key point for them and we also have higher configurations to meet their demands, such as 24 head weigher working with twin baggers design. Except that, both special made platform with conveyor are necessary to complete the whole line on snacks!

MOREVolumetric With Packing Machine On Beans

Different from traditional powder packaging, this system uses a volumetric cup for metering instead of auger filler. This simple design can speed up the feeding speed and improve the packaging speed of the system. The lifting part configures a single bucket elevator to directly lift 40-60L powder into the storage hopper of volumetric cups. Volumetric cups automatically rotate and will combine to the set weight and then unloaded to the packaging machine. This type of packaging system is widely used in various powder packaging, such as coffee powder, flour, seasoning powder, etc.

MOREScrew Conveyor With Packing Machine On Seasoning

This is a system for powder products from packaging to weight inspection. The powder is first agitated from the screw conveyor to the auger filler. The auger filler is a device used for powder metering, and its function is to do quantitative feeding. After the material is down, it enters the vertical packing machine for packaging. After the packaging is completed, the output conveyor is automatically transported to the check weigher for weight detection. This is the machine which is uesd to detect whether the weight of a single product is consistent with the set target, and the sorting device will automatically eliminate products that do not conform the standard. Products that meet the requirements will be conveyed to the turn table. In this way, the whole packaging system is finished. The whole set is linkage control, automatic feeding, stop working without materials.

MOREBowl Conveyor With Packing Machine On Mixture Breakfast

Mixed material packaging system. When a bag requires the mixing of several materials, such as mixed nuts, candies, etc. Different packaging machines are configured according to the type of material and weighing dose. The bowl elevator receives the material of each multihead weigher in sequence, until it reaches the packaging machine directly at the end of the package.

MOREIntegrated Z-shape Conveyor With Multihead Weigher On Biscuits

Integrated Z-shape conveyor is more suitable for the situation where the factory space is limited, accurately weighed by a multi-head weigher, equipped with parcel delivery machine to deliver food desiccant, follow the material into the vertical packaging machine. Perfect match for the biscuits and other snack.

MORE