Premade bag vacuum packaging-powder

Featuring an independent chamber vacuum system, each station is equipped with a sealed chamber for thorough vacuum extraction, especially suitable for oxygen-sensitive fine powders. The machine achieves fully automated continuous operation - bag feeding, opening, dosing, vacuuming, sealing, and output - ensuring stable performance while effectively preventing powder leakage or clumping. Real-time temperature and pressure monitoring guarantees strong, smooth seals. Constructed with 304 stainless steel, it offers wear/corrosion resistance and long-term reliability for industrial powder packaging.

Conveyor / Feeder

A screw feeder, or screw conveyor, utilizes a rotating helical screw (auger) within a tube or trough to reliably move bulk materials. Its primary function is precise, controlled metering and transfer of dry, free-flowing, or semi-solid substances like powders, granules, pellets, flakes, or chips. Screw feeders ensure consistent, dust-controlled material flow from storage (silos, hoppers) to processing equipment (mixers, reactors, packaging lines). Their design offers accuracy, reliability, and containment for diverse materials.

MORENon-standard customized U-tube screw feeders are specialized material handling systems designed for unique industrial challenges. Their defining U-shaped housing securely encloses a rotating screw, efficiently conveying bulk solids – powders, granules, flakes, or pellets – along a defined path. Key functions include precise, controlled feeding of difficult materials (sticky, abrasive, fragile), gentle handling to prevent degradation, and creating a sealed environment to prevent contamination or dust emission. Customization allows tailoring dimensions (length, tube diameter, screw pitch), materials of construction (stainless steel, coatings), hopper design, drive power, and discharge configuration. Applications are diverse, spanning industries requiring specific solutions: precise ingredient dosing in Food & Beverage or Pharmaceutical production, handling abrasive minerals in Chemicals, conveying fragile catalysts in Petrochemicals, managing sticky polymers in Plastics, or automating processes in specialized Agriculture or Recycling plants where standard feeders fall short. They streamline feeding where conventional options fail.

MOREWorking Platform

Measuring Gauge

Packaging Machine

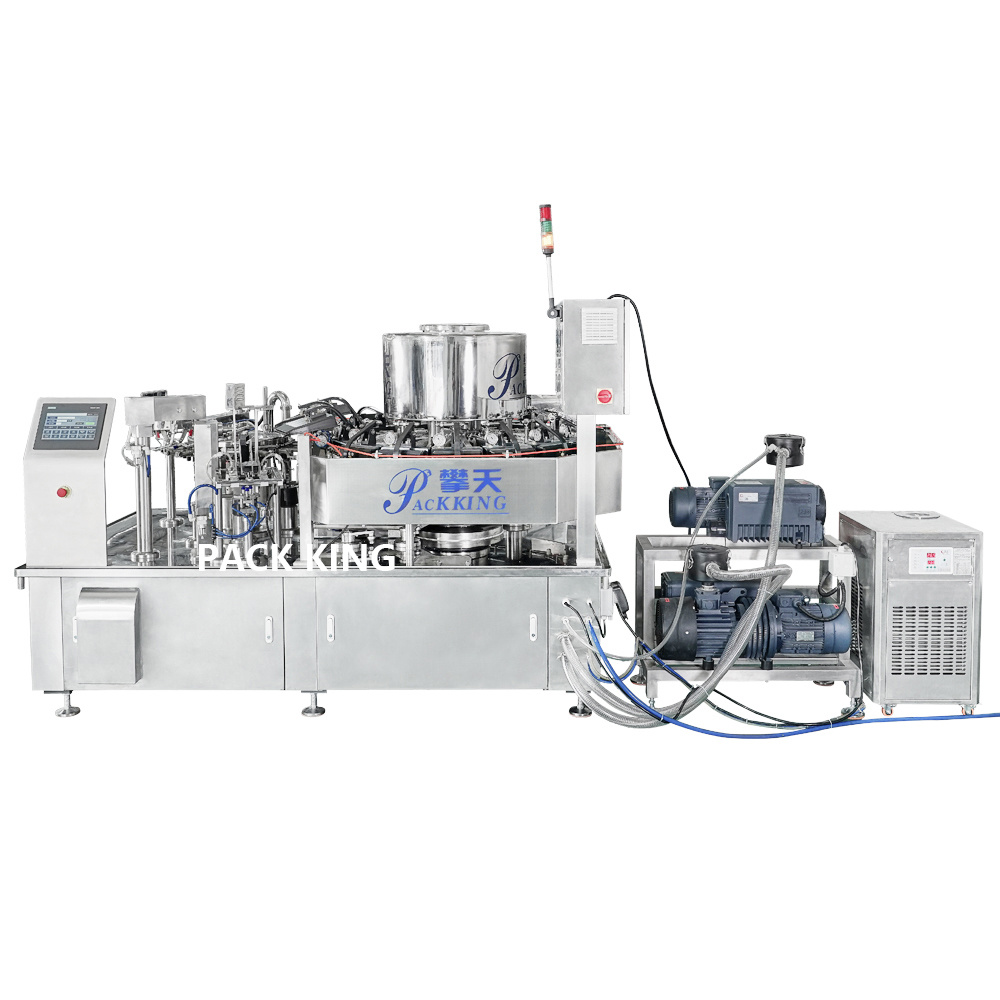

140-16ZK Vacuum premade packer

140-16ZK VACUUM PREMADE PACKER Packing speed:80-120 bags/min(speed is determined by product characteristics and filling weight) Bag Material:Aluminum foil bag,paper bag,nylon bag,etc. Packing bag specification:With:55~110mm Leng:60~190mm Total power:Main machine power≈6kw Air Consumption:0.8m³/min(compressed air supplied by user) Driving power:Standard three-phase 380V 50HZ Machine shape:2500mmx1500mmx1600mm(L*W*H) Main machine weight:3T Environment:Room temperature 10~40 degrees celsius,30~90% RH,no dew,no corrosive gases,no dust and other harsh environments.

MOREPT240-10ZK Vacuum bagging machine

Convenient operation, adopting high-end electrical control system, friendly man-machine interface, easy to operate. No downward material not sealing, unfilled bags can be recycled, no waste of bags. This equipment is suitable for all kinds of prefabricated bag products such as agricultural products, daily necessities, foodstuffs, spices, medicine, hardware, electronic products, agriculture and so on.

MORE