Pillow bag packaging-granules

Our fully automated vertical packaging line delivers exceptional speed and reliability for granular products like seeds, grains, and powders. Featuring advanced multihead weigher for precise dosing, the system integrates product feeding, bag forming, weighing, sealing, and coding in one seamless operation. Intelligent vibration trays prevent bridging, maintaining consistent flow. Built with food-grade stainless steel and user-friendly HMI controls, this line guarantees minimal waste, maximum uptime, and flawless packaging integrity. Elevate efficiency and product appeal with our end-to-end granular packaging solution.

Conveyor / Feeder

Core Functions 1.Adapting to steep angle conveying It solves the problem that ordinary flat conveyor belts are prone to material sliding and low conveying efficiency when the inclination angle is large. Through special structural designs (such as transverse partitions, corrugated ribs, etc.), it can stably convey bulk materials on steep slopes or even in vertical directions, effectively reducing the floor area occupied by the conveying line. 2.Wear resistance and corrosion resistance Polyurethane material itself has excellent wear resistance, tear resistance, and chemical corrosion resistance. It can adapt to the conveying of various materials (such as ores, coal, grain, chemical fertilizers, construction waste, etc.), and is especially suitable for working conditions where the conveyor belt is subject to significant wear or certain corrosiveness. 3.Low noise and environmental friendliness Compared with traditional rubber conveyor belts or metal conveying chains, PU material is relatively soft, resulting in lower noise during operation. Moreover, the material itself is non-toxic and easy to recycle, meeting environmental protection requirements. It is suitable for places with strict restrictions on noise and environment (such as food processing, urban waste treatment, etc.). 4.Flexible adaptation and efficient conveying It can be designed with different structures such as rib heights and partition spacings according to the characteristics of the conveyed materials (particle size, humidity, temperature, etc.) and angle requirements, realizing continuous and efficient material conveying and improving the automation level of the production process. Main Application Fields 1.Mining and metallurgy industry Conveying ore raw materials such as coal, iron ore, and limestone. It is widely used in steep slope conveying scenarios in underground mines or open-pit mines, reducing the difficulty of laying conveying lines due to terrain restrictions. 2.Building materials and chemical industry Used for conveying materials such as cement, sand, glass raw materials, chemical fertilizers, and plastic particles. Its corrosion resistance and wear resistance make it suitable for the special conveying needs of chemical raw materials. Agriculture and grain processing 3.Conveying agricultural products such as grains, beans, and feed. The environmental friendliness and low noise characteristics of PU materials make them suitable for scenarios in contact with food, and can prevent materials from sliding during inclined conveying in storage and processing links. 4.Construction waste and waste treatment In scenarios such as demolition sites, landfills, and waste recycling plants, it is used to convey mixed materials such as construction waste and domestic waste. The steep angle design can save site space and improve processing efficiency. 5.Port and logistics conveying In the bulk material loading and unloading links of ports and stations, it is used to convey materials (such as coal, grain) from ships and trucks to storage facilities through inclined lines, enhancing the continuity of loading and unloading operations.

MOREPP Bowl conveyor Functions: 1.High-Strength Conveying:304 stainless steel boasts high hardness, capable of carrying heavy particles and bulk materials (such as metal parts and ore fragments), and boasts strong impact resistance and excellent deformation resistance. 2.Hygienic and Easy-Clean:The surface is smooth and non-porous, meeting food-grade (FDA) and pharmaceutical-grade (GMP) standards, and can be sterilized at high temperatures or chemically disinfected. 3.Avoids electrostatic attraction issues that may arise from plastic materials, making it suitable for dust-prone and explosive environments (requires an explosion-proof motor). Application: PP plastic bowl elevator is an ideal choice for industries such as food, medicine, and chemical industry due to its hygienic, corrosion-resistant and lightweight features. It is especially suitable for scenes with high requirements for cleanliness or rust prevention.

MOREPP modular belt take away conveyor

PP modular take away conveyors, made of food-grade material. They are ideal for dry food finished products like biscuits, puffed snacks, frozen pastries, baked goods, as well as pharmaceutical capsules and clean plastic parts with high hygiene requirements, ensuring clean and stable conveying.

MOREPP bucket elevator The Z-type elevator transports materials by continuously moving buckets attached to a chain Z-shaped path. The buckets are loaded at the bottom horizontal section, elevated vertically, and then discharged at the top horizontal section by tipping or tilting, enabling efficient, enclosed conveyance of powdered and granular materials between multiple floors. Mainly used for conveying good fluidity of food, crops, such as: peanuts, soybeans, rice, candy, dried fruit and other food, but also used for hardware, chemical, pharmaceutical, granular material transportation. Z- bucket elevators allow feeding control in one or more positions and can be easily inter-operated with various types of feeding devices. All components have easy removal inspection covers and easy positioning inspection Windows. The bucket has a quick release mechanism for quick installation or removal of the bucket. All elevators are equipped with automatic zippers and built- in overload protection.

MOREWorking Platform

Online Sale Vertical Supporting Working Platforms For Whole Conveying Line Packing System

1. Stainless steel/aluminum surface, aluminum floor and steps, stainless steel handrails/ support legs. 2. Strong and generous, durable. 3. The platform is beautiful, anti- skid and safe. 4. Simple structure, easy to maintain. 5. Small energy consumption and low use cost. 6. Low noise, suitable for quieter working environment. 7. The conveying is stable, the material and the conveyor belt have no relative movement, can avoid the damage to the conveying material. 8. Oil resistance, corrosion resistance, anti- static. 9. Impact resistance and shock absorption.

MOREMeasuring Gauge

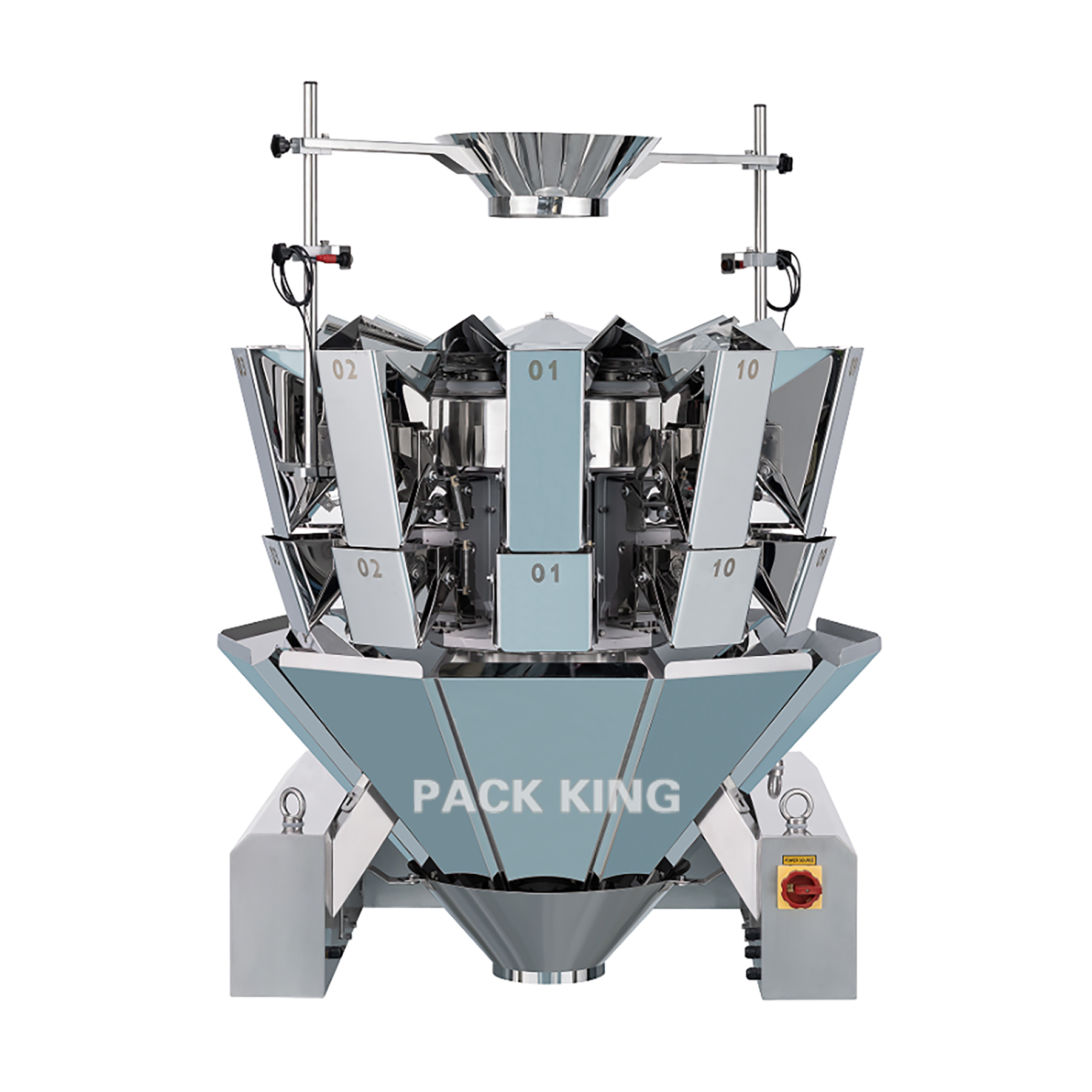

Features ❊ Individually adjust the amplitude during operation for easy operation. ❊ Multi-language operation, suitable for global markets. ❊ Controlled weighing and sequential material discharge prevents material blockage. ❊ Professional digital weighing module with high accuracy and excellent stability. ❊ Modular stepper motor drive for easy maintenance. Applicable Products It is suitable for quantitative weighing of common specifications of materials, such as candy/peanuts/snacks/potato chips/nuts/jelly/biscuits/bread/coffee beans/pet food/dry particles or hardware, vegetable salad/fruit salad/potatoes/onions and other vegetables/fruits with large target weight or large capacity.

MOREFeatures ❊ Individually adjust the amplitude during operation for easy operation. ❊ Multi-language operation, suitable for global markets. ❊ Control weighing and sequential material discharge to prevent material blockage. ❊ Professional digital weighing module with high accuracy and excellent stability. ❊ Modular stepper motor drive for easy maintenance. Applicable Products Suitable for common specifications of materials, candy/peanuts/snacks/potato chips/nuts/jelly/biscuits/bread/coffee beans/pet food/dry particles or hardware, etc.

MOREPackaging Machine

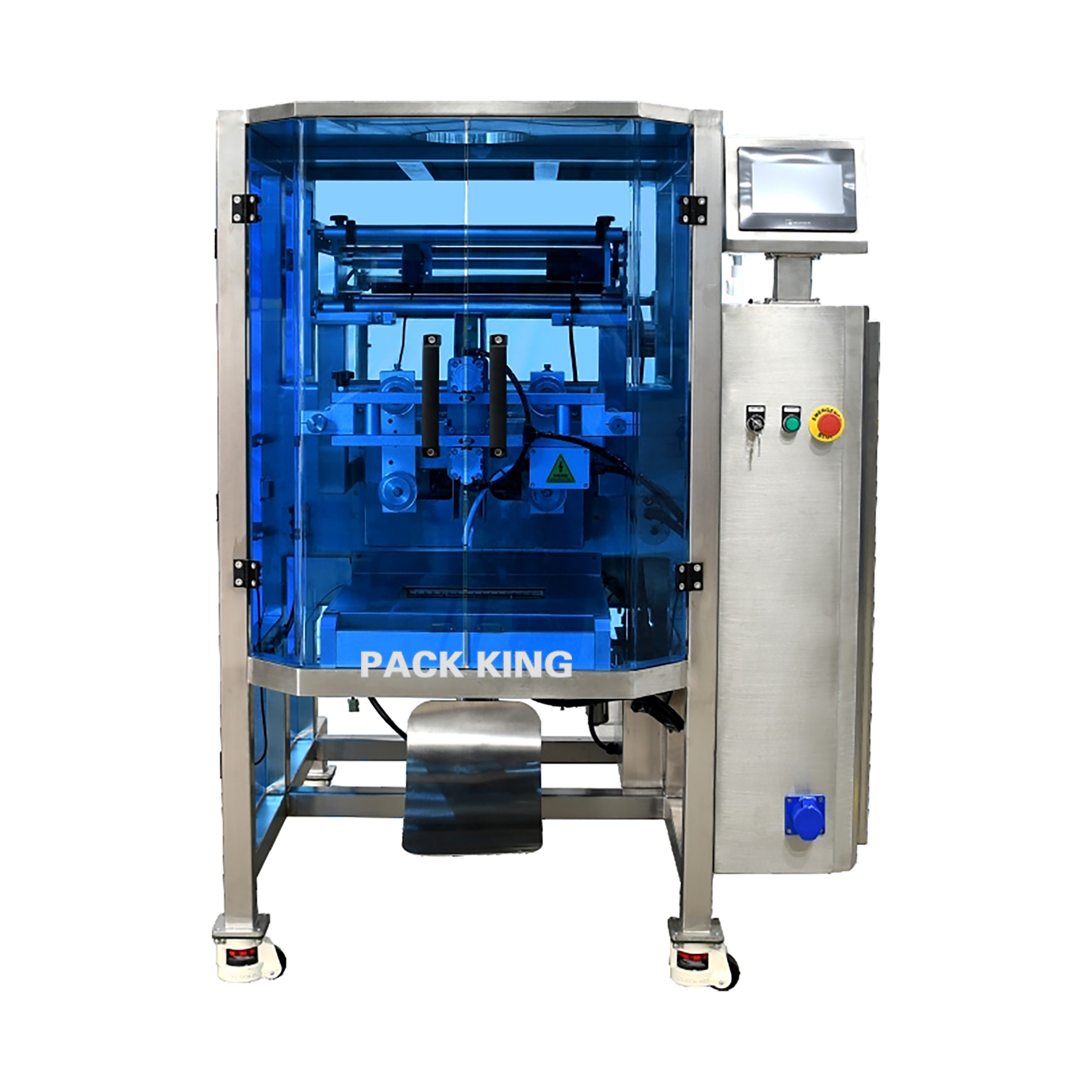

VP420 Vertical packaging machine

1, the machine design advanced, reasonable structure, reliable performance 2, adopt double synchronous belt pull film, by cylinder control tensioning, automatic deviation correction, automatic alarm protection function, minimize loss. 3, this machine is matched with measuring device, set bag making, filling, filling, printing, counting in one. 4, can be modified according to the material open and close metering device

MOREVP520 Vertical packaging machine

1, the machine design advanced, reasonable structure, reliable performance 2, adopt double synchronous belt pull film, by cylinder control tensioning, automatic deviation correction, automatic alarm protection function, minimize loss. 3, this machine is matched with measuring device, set bag making, filling, filling, printing, counting in one. 4, can be modified according to the material open and close metering device

MOREVP620 Vertical packaging machine

1, the machine design advanced, reasonable structure, reliable performance 2, adopt double synchronous belt pull film, by cylinder control tensioning, automatic deviation correction, automatic alarm protection function, minimize loss. 3, this machine is matched with measuring device, set bag making, filling, filling, printing, counting in one. 4, can be modified according to the material open and close metering device

MOREVP820 Vertical Packaging Machine

1、Fully automatic weighing system 2、Fully automatic film drawing 3、Automatic bag making 4、Automatic bag making

MOREVTQ420 Inclined Packaging Machine

Product Advantages Patented tilting structure design, tilting down the material to protect the productsthat are easy to fall and break, such as puffed frozen food, frozen dumplings.cookies, fruits and so on. The appearance of the machine is luxurious and high-grade, and the sturdyprotection door has good waterproof and protection function. More than 90% of the parts are made of 304 stainless steel, high quality, longermachine life. Electrical components adopt big brand, quality assurance, the machine runs more smoothly. The coder is installed upside down, easier to adjust and replace. Newly upgraded and improved formers make the bag shape more high-gradeand beautiful.

MORE