PU belt conveyor

Packaging Speed

bags/min

Product Application

Core Functions

1.Adapting to steep angle conveying

It solves the problem that ordinary flat conveyor belts are prone to material sliding and low conveying efficiency when the inclination angle is large. Through special structural designs (such as transverse partitions, corrugated ribs, etc.), it can stably convey bulk materials on steep slopes or even in vertical directions, effectively reducing the floor area occupied by the conveying line.

2.Wear resistance and corrosion resistance

Polyurethane material itself has excellent wear resistance, tear resistance, and chemical corrosion resistance. It can adapt to the conveying of various materials (such as ores, coal, grain, chemical fertilizers, construction waste, etc.), and is especially suitable for working conditions where the conveyor belt is subject to significant wear or certain corrosiveness.

3.Low noise and environmental friendliness

Compared with traditional rubber conveyor belts or metal conveying chains, PU material is relatively soft, resulting in lower noise during operation. Moreover, the material itself is non-toxic and easy to recycle, meeting environmental protection requirements. It is suitable for places with strict restrictions on noise and environment (such as food processing, urban waste treatment, etc.).

4.Flexible adaptation and efficient conveying

It can be designed with different structures such as rib heights and partition spacings according to the characteristics of the conveyed materials (particle size, humidity, temperature, etc.) and angle requirements, realizing continuous and efficient material conveying and improving the automation level of the production process.

Main Application Fields

1.Mining and metallurgy industry

Conveying ore raw materials such as coal, iron ore, and limestone. It is widely used in steep slope conveying scenarios in underground mines or open-pit mines, reducing the difficulty of laying conveying lines due to terrain restrictions.

2.Building materials and chemical industry

Used for conveying materials such as cement, sand, glass raw materials, chemical fertilizers, and plastic particles. Its corrosion resistance and wear resistance make it suitable for the special conveying needs of chemical raw materials.

Agriculture and grain processing

3.Conveying agricultural products such as grains, beans, and feed. The environmental friendliness and low noise characteristics of PU materials make them suitable for scenarios in contact with food, and can prevent materials from sliding during inclined conveying in storage and processing links.

4.Construction waste and waste treatment

In scenarios such as demolition sites, landfills, and waste recycling plants, it is used to convey mixed materials such as construction waste and domestic waste. The steep angle design can save site space and improve processing efficiency.

- Port and logistics conveying

In the bulk material loading and unloading links of ports and stations, it is used to convey materials (such as coal, grain) from ships and trucks to storage facilities through inclined lines, enhancing the continuity of loading and unloading operations.

Applicable Bag Type

Keyword:

0

0

Related Products

100-16ZK+ Automatic screw feeder

100-16ZK+AUTOMATIC SCREW FEEDER Packing speed:80-110 bags/min(speed is determined by product characteristics and filling weight) Bag Material:Aluminum foil bag,paper bag,nylon bag,etc. Packing bag specification:With:55~110mm Leng:60~190mm Total power:Main machine power≈6kw Air Consumption:0.8m³/min(compressed air supplied by user) Driving power:Standard three-phase 380V 50HZ Machine shape:2500mmx1500mmx1600mm(L*W*H) Main machine weight:3T Environment:Room temperature 10~40 degrees celsius,30~90% RH,no dew,no corrosive gases,no dust and other harsh environments.

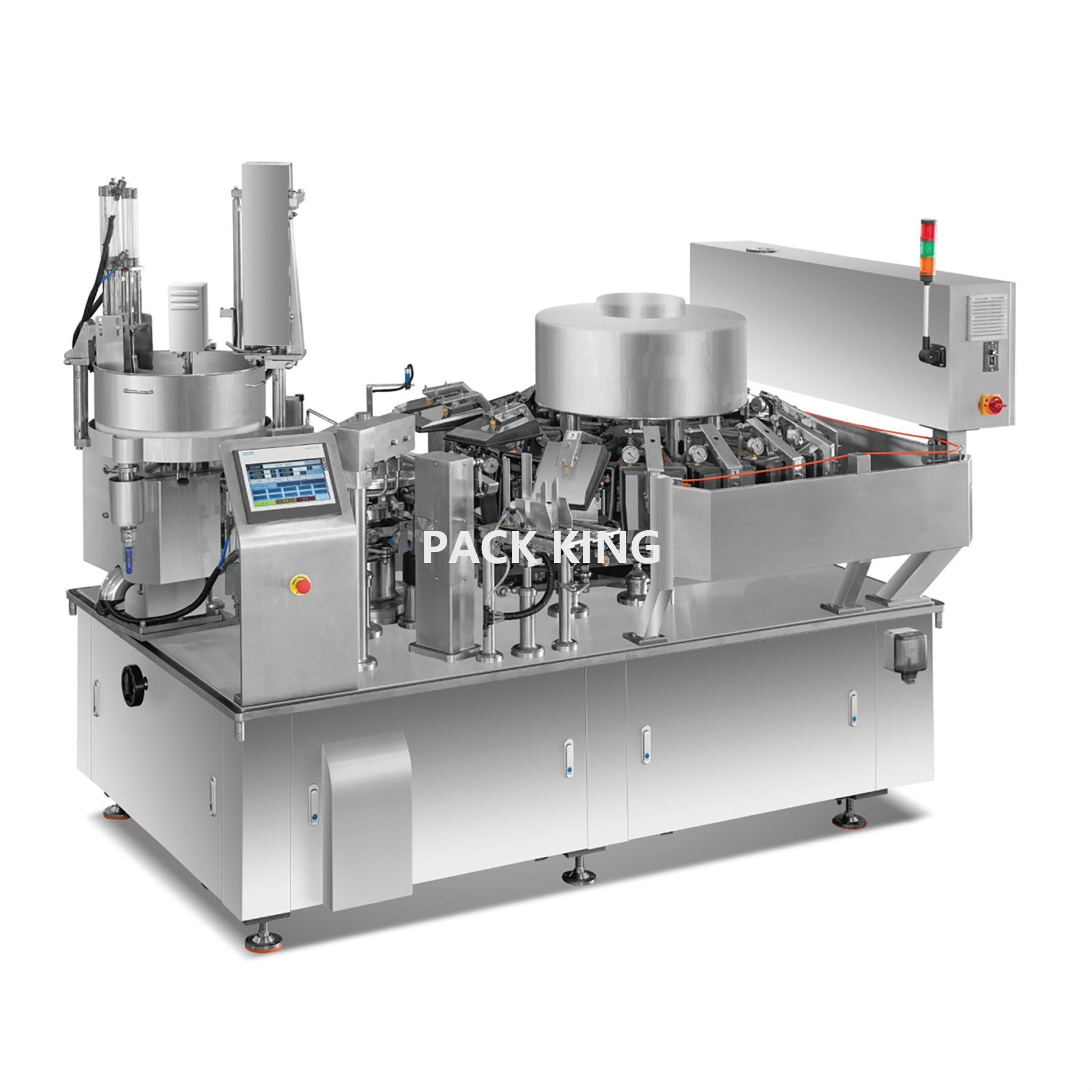

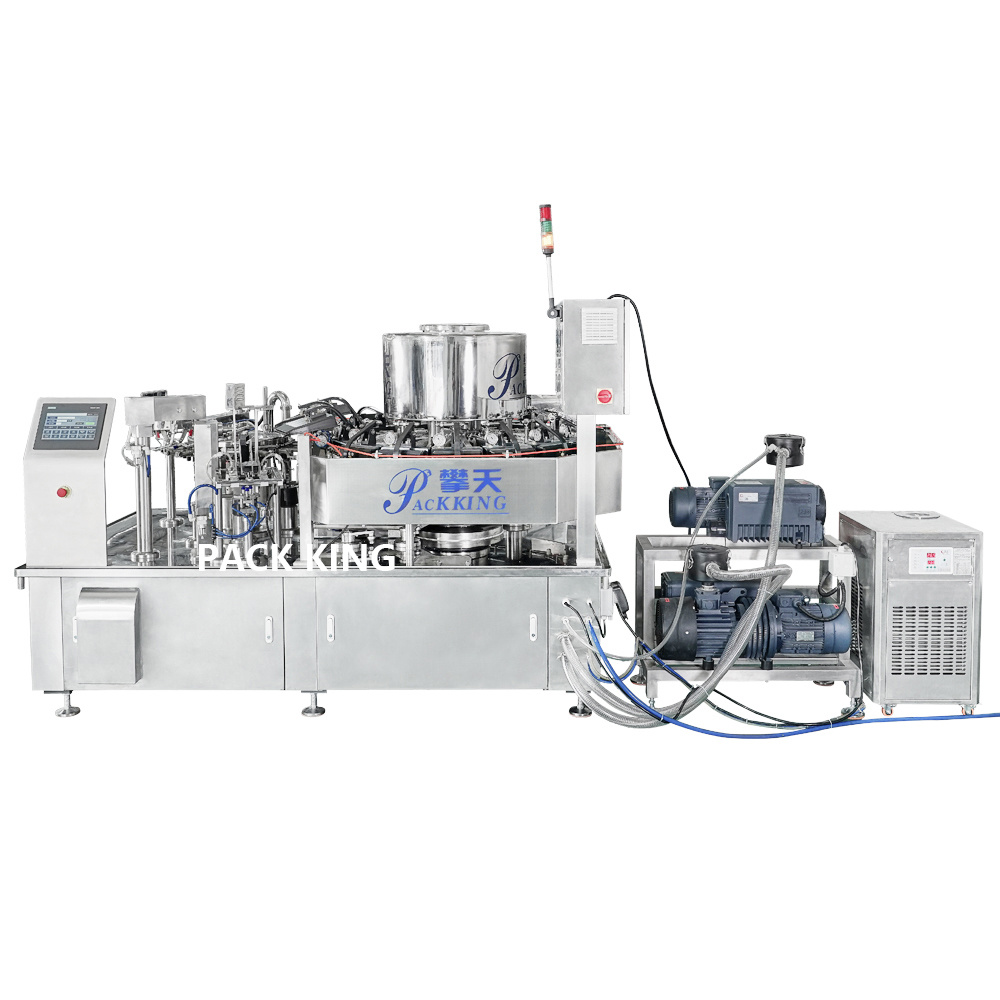

MORE140-16ZK Vacuum premade packer

140-16ZK VACUUM PREMADE PACKER Packing speed:80-120 bags/min(speed is determined by product characteristics and filling weight) Bag Material:Aluminum foil bag,paper bag,nylon bag,etc. Packing bag specification:With:55~110mm Leng:60~190mm Total power:Main machine power≈6kw Air Consumption:0.8m³/min(compressed air supplied by user) Driving power:Standard three-phase 380V 50HZ Machine shape:2500mmx1500mmx1600mm(L*W*H) Main machine weight:3T Environment:Room temperature 10~40 degrees celsius,30~90% RH,no dew,no corrosive gases,no dust and other harsh environments.

MOREFeatures 1、Fully automatic rotary 8 station intermittent rotary preformed bag dispensing, opening and closing. 2、Versatile in design, easy to link up with other down stream packaging equipment such as liquid filler, multi-heads weigher, metal detector, check weigher, case sealer, etc. 3、Strict mechanical safety standards to ensure stable operation of machinery and increase packaging speed. 4、Heavy parts are used to improve the durability of machinery. 5、The simple design of the touch screen control system facilitates the use of operators, and is simple and easy to use. 6、Improve the solution, reduce the cost for you. 7、The production line meets the requirements of food hygiene and is convenient to clean. 8、Automatic control of a series of processes from loading, filling, sealing, and finished products. 9、Automatic lubrication system.

MOREPT100 -16ZK Measuring cup filler

The main optional equipment Material measuring and filling machine, working platform, weight selection scale, material elevator, finished product conveying elevator, metal detecting machine, printing code machine.

MORE