PP chain belt conveyor

Packaging Speed

bags/min

Product Application

Features and Advantages

*Large conveying angle: By setting special push plates and skirts, it can effectively prevent materials from sliding down, enabling large-angle conveying. The lifting angle can reach 30-40 degrees or even higher. When space and product shape permit, it can replace continuous elevators.

*Strong bearing capacity: With a robust structure, it can be used in heavy-duty conveying operations and is suitable for occasions with impact at loading and unloading points. It can convey large and sharp materials, and the weight of a single material (piece) being transported can reach 70-120kg.

*Wide application range: There are various chain plate materials available, which can be selected according to different material characteristics and usage environments. For example, stainless steel is suitable for industries with high hygiene requirements such as food and pharmaceuticals; plastic-steel chain plates are resistant to acid, alkali, salt water, etc., and can be used in various harsh environments.

*Stable and reliable operation: Adopting chain transmission, it runs smoothly with low noise and little wear. The chain has undergone heat treatment, featuring good wear resistance and a long service life. Meanwhile, the equipment has good sealing performance, which can prevent material leakage and ensure the cleanliness of the production environment.

Application Fields

*Food industry: Used for conveying fruits, poultry, canned drinks, cosmetics and cleaning products, etc., and can meet the needs of automatic conveying, grading and packaging.

*Chemical industry: Suitable for conveying various chemical raw materials, such as granular and powdery materials, and can operate stably in corrosive environments.

*Mining industry: Can be used to convey ores, slag, etc., and can adapt to the harsh working environment of mines, especially suitable for conveying large and sharp materials.

*Other industries: Also widely used in electronics, electrical appliances, automobile, logistics and other industries for conveying various parts, packaged items, etc.

Applicable Bag Type

Keyword:

0

0

Related Products

100-16ZK+ Automatic screw feeder

100-16ZK+AUTOMATIC SCREW FEEDER Packing speed:80-110 bags/min(speed is determined by product characteristics and filling weight) Bag Material:Aluminum foil bag,paper bag,nylon bag,etc. Packing bag specification:With:55~110mm Leng:60~190mm Total power:Main machine power≈6kw Air Consumption:0.8m³/min(compressed air supplied by user) Driving power:Standard three-phase 380V 50HZ Machine shape:2500mmx1500mmx1600mm(L*W*H) Main machine weight:3T Environment:Room temperature 10~40 degrees celsius,30~90% RH,no dew,no corrosive gases,no dust and other harsh environments.

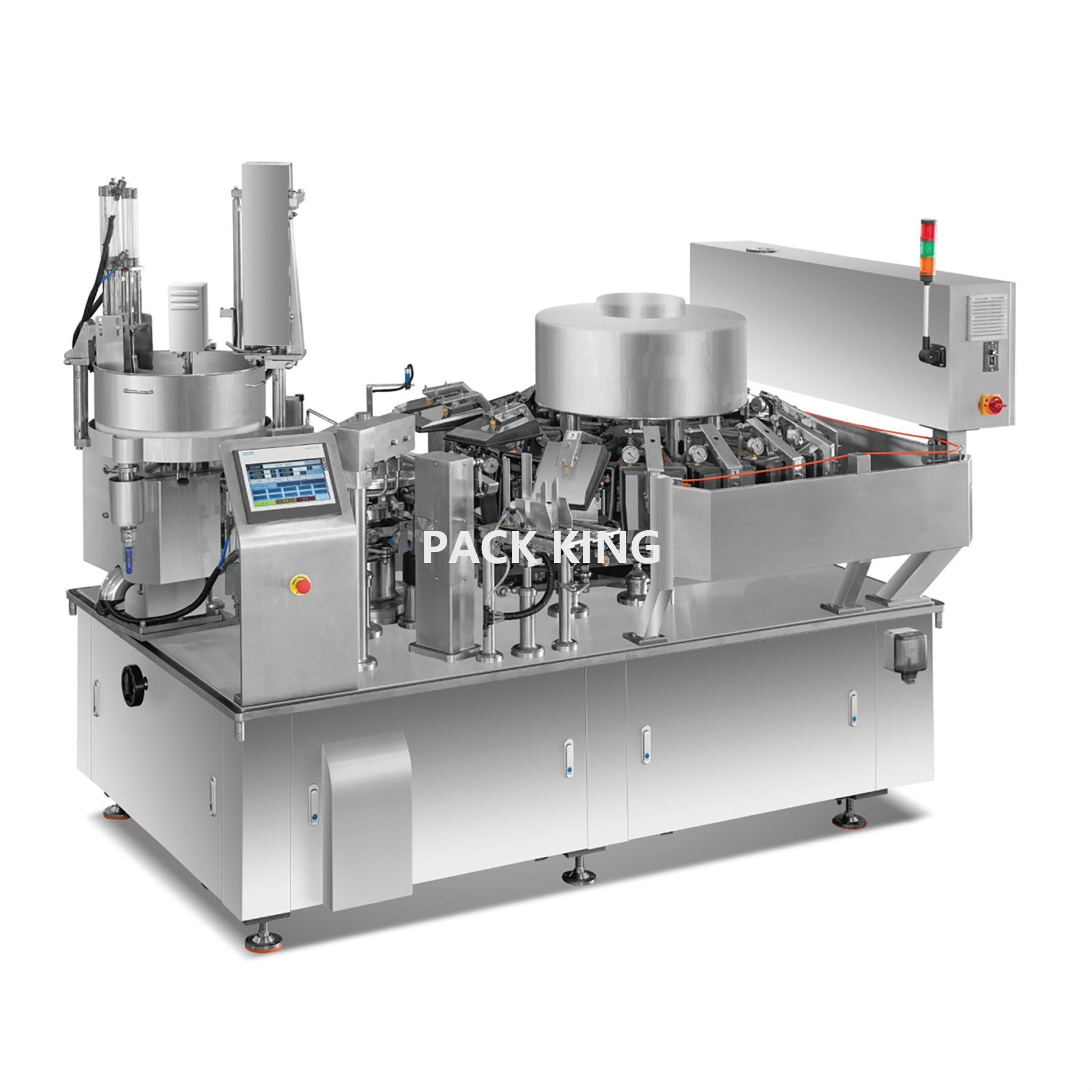

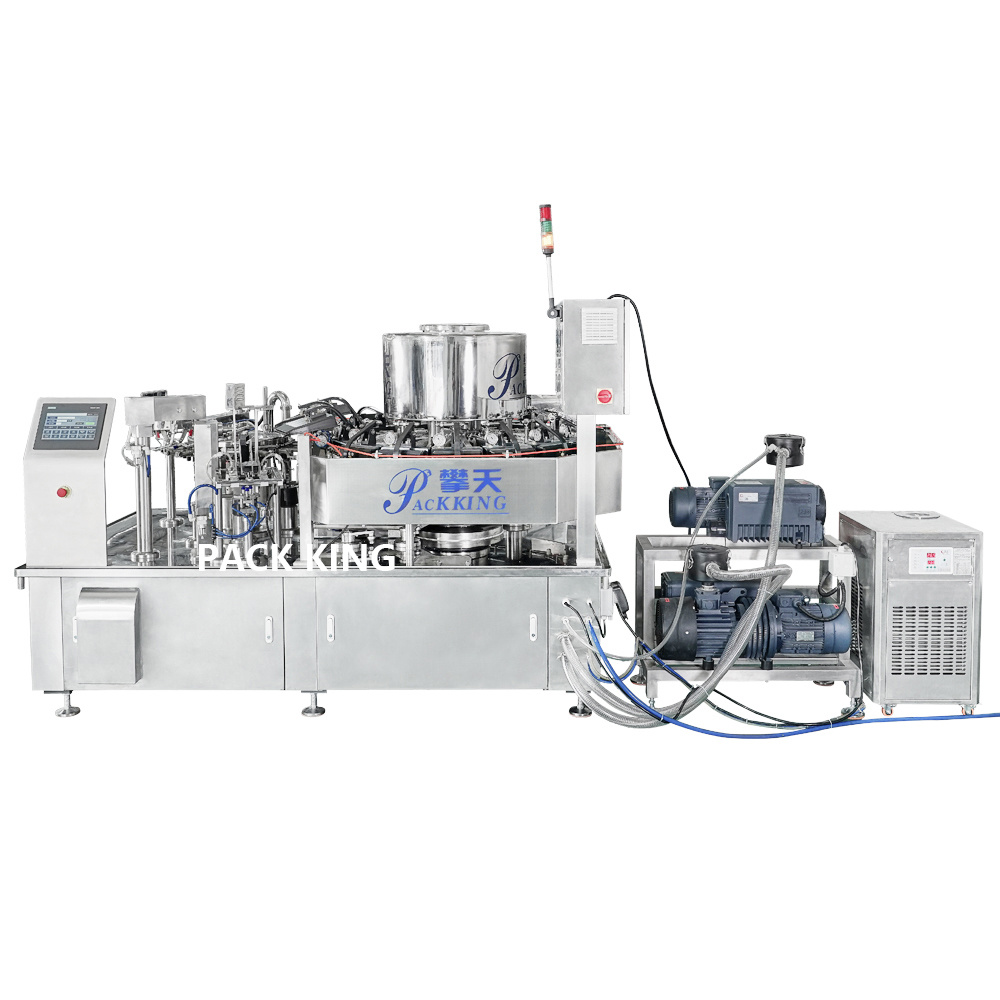

MORE140-16ZK Vacuum premade packer

140-16ZK VACUUM PREMADE PACKER Packing speed:80-120 bags/min(speed is determined by product characteristics and filling weight) Bag Material:Aluminum foil bag,paper bag,nylon bag,etc. Packing bag specification:With:55~110mm Leng:60~190mm Total power:Main machine power≈6kw Air Consumption:0.8m³/min(compressed air supplied by user) Driving power:Standard three-phase 380V 50HZ Machine shape:2500mmx1500mmx1600mm(L*W*H) Main machine weight:3T Environment:Room temperature 10~40 degrees celsius,30~90% RH,no dew,no corrosive gases,no dust and other harsh environments.

MOREFeatures 1、Fully automatic rotary 8 station intermittent rotary preformed bag dispensing, opening and closing. 2、Versatile in design, easy to link up with other down stream packaging equipment such as liquid filler, multi-heads weigher, metal detector, check weigher, case sealer, etc. 3、Strict mechanical safety standards to ensure stable operation of machinery and increase packaging speed. 4、Heavy parts are used to improve the durability of machinery. 5、The simple design of the touch screen control system facilitates the use of operators, and is simple and easy to use. 6、Improve the solution, reduce the cost for you. 7、The production line meets the requirements of food hygiene and is convenient to clean. 8、Automatic control of a series of processes from loading, filling, sealing, and finished products. 9、Automatic lubrication system.

MOREPT100 -16ZK Measuring cup filler

The main optional equipment Material measuring and filling machine, working platform, weight selection scale, material elevator, finished product conveying elevator, metal detecting machine, printing code machine.

MORE