PVC belt conveyor

Packaging Speed

bags/min

Product Application

Function

1.Enabling stable conveying at large angles

Ordinary conveyor belts are prone to material sliding and spilling when the inclination angle is large. However, the PVC steep angle conveyor belt, through a combined design of corrugated sidewalls (preventing lateral sliding of materials) and transverse partitions (supporting materials and forming a "hopper" structure), can firmly "lock" materials on steep slopes or even in vertical directions. This ensures that bulk or lumpy materials such as coal, ores, and grains do not fall off, enabling continuous and stable conveying.

Saving space and reducing costs

2.Compared with traditional inclined conveying equipment (such as screw conveyors and bucket elevators), it can be directly arranged along steep angles, significantly shortening the length of the conveying line and reducing the floor area. It is particularly suitable for working conditions with narrow spaces (such as inside workshops and underground mines), lowering the costs of equipment installation and site construction.

Utilizing the characteristic advantages of PVC materials

Corrosion resistance: PVC materials have a certain resistance to acids, alkalis, salt spray, etc., and can convey materials with slight corrosiveness (such as chemical fertilizers and chemical raw materials), extending the service life of the conveyor belt.

3.Hygiene: Food-grade PVC steep angle conveyor belts can be used for conveying food-related materials such as grains and feed. Their surfaces are easy to clean and meet hygiene standards.

Lightweight and low noise: PVC materials have low density, making the conveyor belt lightweight overall. The friction noise with equipment during operation is low, making it suitable for noise-sensitive environments (such as urban waste treatment stations and food processing plants).

- Adapting to various materials and working conditions

The structural parameters such as the height of sidewalls and the spacing of partitions can be adjusted according to the characteristics of materials (particle size, humidity, temperature) to adapt to materials of different forms such as dry powder, granules, and small lumps. It can also work stably in normal or medium-low temperature environments ranging from -10℃ to 60℃.

II. Main Application Fields

1.Mining and coal industry

Conveying ore raw materials such as coal, iron ore powder, and limestone. It is especially suitable for steep terrain in underground or open-pit mines, solving the problem that traditional conveyor belts cannot be arranged due to angle restrictions and improving the efficiency of material transfer in mines.

2.Construction and building materials industry

In cement plants and sand and gravel factories, it conveys bulk building materials such as cement, sand, and crushed stones. It can lift materials from the ground to storage silos or mixing stations, saving the floor area of the conveying line in the factory area.

3.Agriculture and grain processing

Conveying agricultural products such as grains, beans, and feed. Taking advantage of its hygiene and anti-spilling features, it realizes vertical or large-angle lifting in storage and processing links, reducing material loss.

4.Waste treatment and environmental protection industry

Used for sorting and conveying urban domestic waste and construction waste. In places such as waste incineration plants and landfills, mixed waste is lifted to processing equipment through the large-angle design, saving site space.

5.Chemical industry and light industry

Conveying chemical raw materials such as fertilizer granules and plastic particles. With the corrosion resistance of PVC materials, it adapts to mild chemical environments, and optimizes the layout of workshop production lines through large-angle conveying.

Applicable Bag Type

Keyword:

0

0

Related Products

100-16ZK+ Automatic screw feeder

100-16ZK+AUTOMATIC SCREW FEEDER Packing speed:80-110 bags/min(speed is determined by product characteristics and filling weight) Bag Material:Aluminum foil bag,paper bag,nylon bag,etc. Packing bag specification:With:55~110mm Leng:60~190mm Total power:Main machine power≈6kw Air Consumption:0.8m³/min(compressed air supplied by user) Driving power:Standard three-phase 380V 50HZ Machine shape:2500mmx1500mmx1600mm(L*W*H) Main machine weight:3T Environment:Room temperature 10~40 degrees celsius,30~90% RH,no dew,no corrosive gases,no dust and other harsh environments.

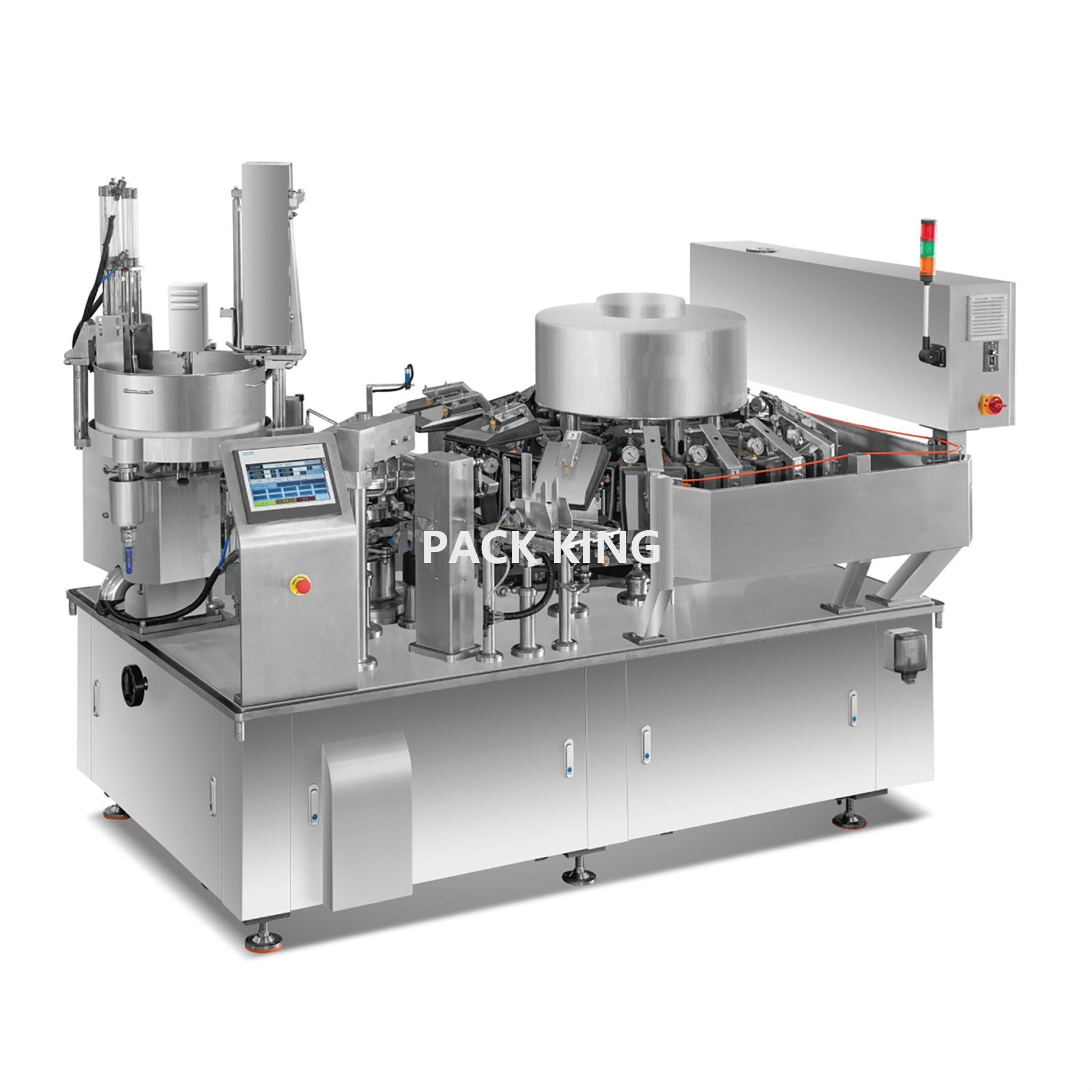

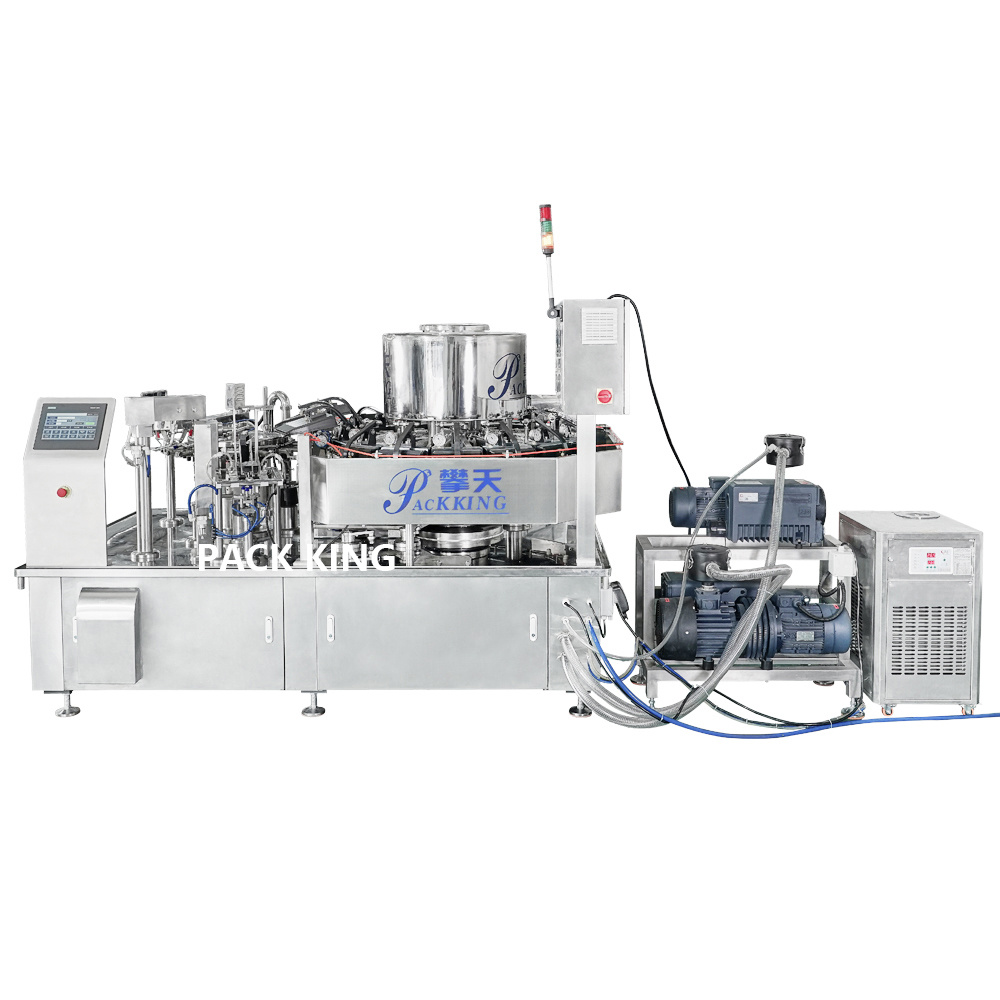

MORE140-16ZK Vacuum premade packer

140-16ZK VACUUM PREMADE PACKER Packing speed:80-120 bags/min(speed is determined by product characteristics and filling weight) Bag Material:Aluminum foil bag,paper bag,nylon bag,etc. Packing bag specification:With:55~110mm Leng:60~190mm Total power:Main machine power≈6kw Air Consumption:0.8m³/min(compressed air supplied by user) Driving power:Standard three-phase 380V 50HZ Machine shape:2500mmx1500mmx1600mm(L*W*H) Main machine weight:3T Environment:Room temperature 10~40 degrees celsius,30~90% RH,no dew,no corrosive gases,no dust and other harsh environments.

MOREFeatures 1、Fully automatic rotary 8 station intermittent rotary preformed bag dispensing, opening and closing. 2、Versatile in design, easy to link up with other down stream packaging equipment such as liquid filler, multi-heads weigher, metal detector, check weigher, case sealer, etc. 3、Strict mechanical safety standards to ensure stable operation of machinery and increase packaging speed. 4、Heavy parts are used to improve the durability of machinery. 5、The simple design of the touch screen control system facilitates the use of operators, and is simple and easy to use. 6、Improve the solution, reduce the cost for you. 7、The production line meets the requirements of food hygiene and is convenient to clean. 8、Automatic control of a series of processes from loading, filling, sealing, and finished products. 9、Automatic lubrication system.

MOREPT100 -16ZK Measuring cup filler

The main optional equipment Material measuring and filling machine, working platform, weight selection scale, material elevator, finished product conveying elevator, metal detecting machine, printing code machine.

MORE