Multiple outlets elevator

Packaging Speed

bags/min

Product Application

Multiple outlet elevator

The multi-discharge Z-type elevator intelligently diverts materials through multiple discharge points along its vertical lift section. Utilizing programmable controls or mechanical baffles, it precisely distributes materials to different floors or production lines, making it ideal for food processing raw material allocation, pharmaceutical multi-stage processes, and recycling material sorting. Its "one-machine-multi-outlet" design maximizes space efficiency while PLC automation enables hygienic, closed-loop multi-destination conveying.

The multi-discharge Z-type elevator is ideally suited for puffed food production, featuring gentle handling of delicate snacks like chips and popcorn through its enclosed stainless steel construction. Its intelligent diverting system enables simultaneous cooling via perforated buckets, multi-flavor seasoning through programmable diverter valves, and automated packaging sorting by format and weight - all while maintaining product integrity and meeting strict food safety standards. The system's vibration control and quick-change components allow efficient processing of diverse products from rice cakes to protein-enriched snacks, making it indispensable for modern snack food manufacturing that requires both precision and flexibility.

The multi-discharge Z-type elevator is specifically engineered for handling various puffed food products with precision and care, including crispy potato chips requiring oil drainage, delicate cheese puffs needing gentle transport, protein-enriched health snacks demanding accurate sorting, flavored extruded cereals for multi-line seasoning, and functional fortified foods requiring hygienic transfer. Its specialized design features like vibration-dampened conveying, anti-stick surfaces, and weight-based sorting capabilities make it ideal for modern snack production lines that process everything from traditional corn puffs to innovative plant-based crispy products while maintaining strict food safety standards and product integrity throughout cooling, flavoring, and packaging stages.

Applicable Bag Type

Keyword:

0

0

Related Products

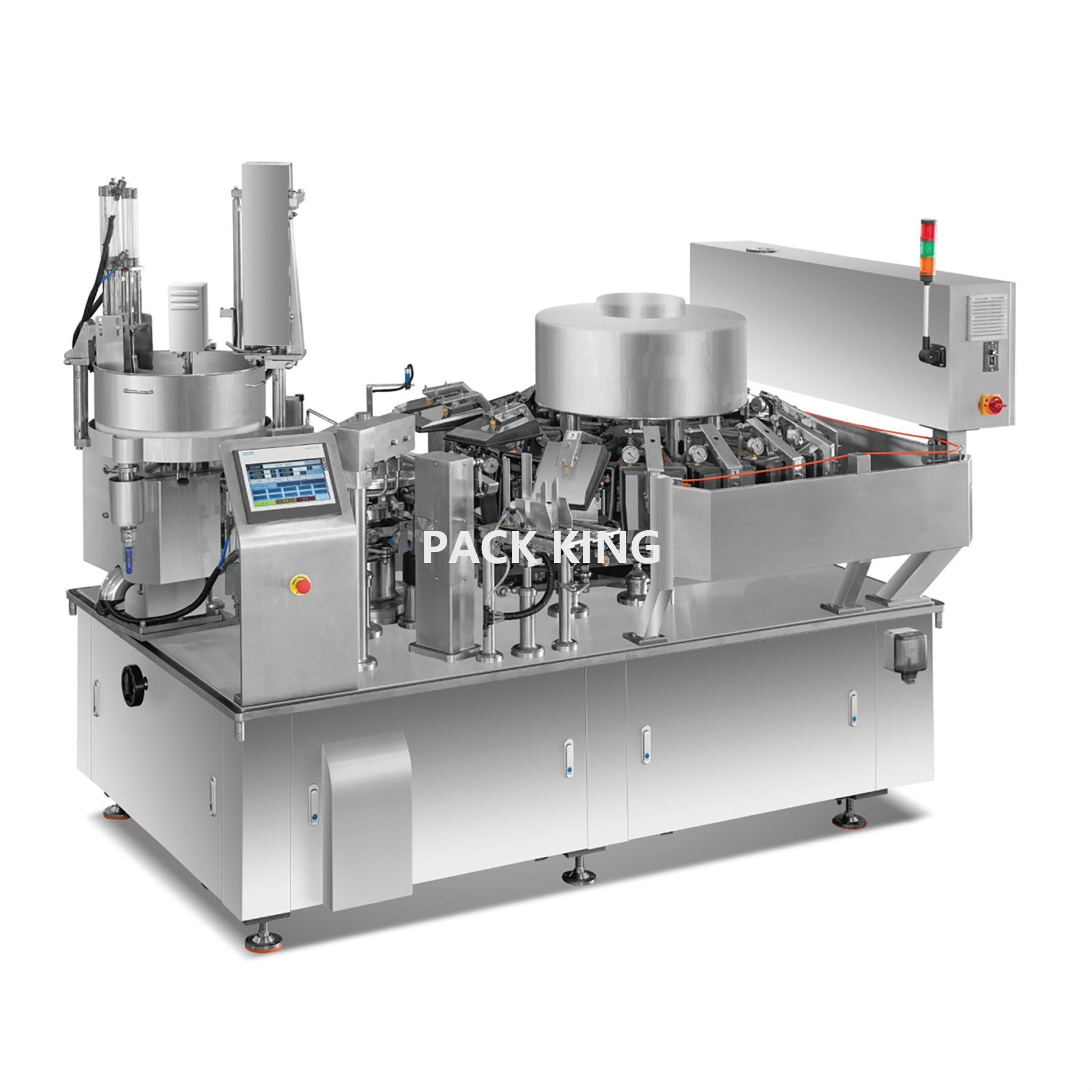

100-16ZK+ Automatic screw feeder

100-16ZK+AUTOMATIC SCREW FEEDER Packing speed:80-110 bags/min(speed is determined by product characteristics and filling weight) Bag Material:Aluminum foil bag,paper bag,nylon bag,etc. Packing bag specification:With:55~110mm Leng:60~190mm Total power:Main machine power≈6kw Air Consumption:0.8m³/min(compressed air supplied by user) Driving power:Standard three-phase 380V 50HZ Machine shape:2500mmx1500mmx1600mm(L*W*H) Main machine weight:3T Environment:Room temperature 10~40 degrees celsius,30~90% RH,no dew,no corrosive gases,no dust and other harsh environments.

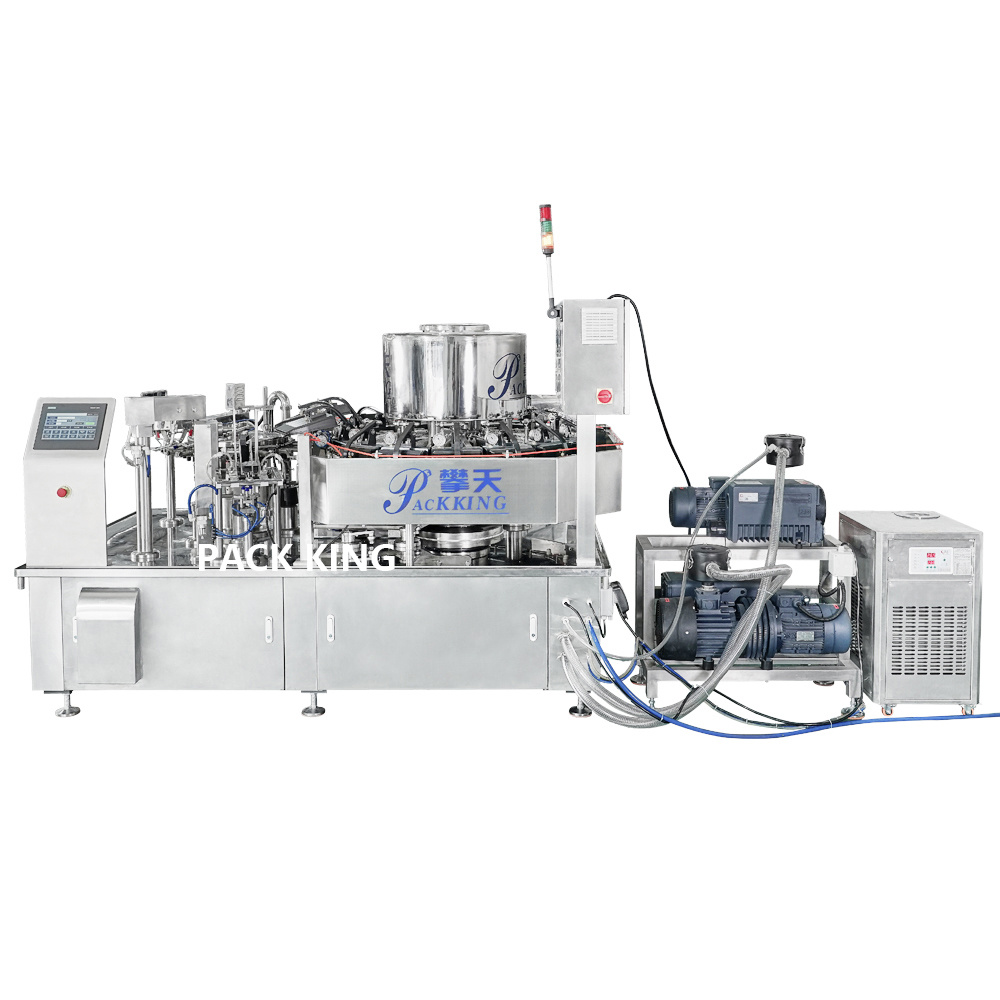

MORE140-16ZK Vacuum premade packer

140-16ZK VACUUM PREMADE PACKER Packing speed:80-120 bags/min(speed is determined by product characteristics and filling weight) Bag Material:Aluminum foil bag,paper bag,nylon bag,etc. Packing bag specification:With:55~110mm Leng:60~190mm Total power:Main machine power≈6kw Air Consumption:0.8m³/min(compressed air supplied by user) Driving power:Standard three-phase 380V 50HZ Machine shape:2500mmx1500mmx1600mm(L*W*H) Main machine weight:3T Environment:Room temperature 10~40 degrees celsius,30~90% RH,no dew,no corrosive gases,no dust and other harsh environments.

MOREFeatures 1、Fully automatic rotary 8 station intermittent rotary preformed bag dispensing, opening and closing. 2、Versatile in design, easy to link up with other down stream packaging equipment such as liquid filler, multi-heads weigher, metal detector, check weigher, case sealer, etc. 3、Strict mechanical safety standards to ensure stable operation of machinery and increase packaging speed. 4、Heavy parts are used to improve the durability of machinery. 5、The simple design of the touch screen control system facilitates the use of operators, and is simple and easy to use. 6、Improve the solution, reduce the cost for you. 7、The production line meets the requirements of food hygiene and is convenient to clean. 8、Automatic control of a series of processes from loading, filling, sealing, and finished products. 9、Automatic lubrication system.

MOREPT100 -16ZK Measuring cup filler

The main optional equipment Material measuring and filling machine, working platform, weight selection scale, material elevator, finished product conveying elevator, metal detecting machine, printing code machine.

MORE