Premade bag vacuum packaging-granules

The bag-giving vacuum packaging machine has a wide range of applications. It is not only suitable for food granular products, such as grains (rice, millet), nuts (walnuts, almonds), beans (soybeans, red beans), leisure foods (potato chips, biscuit granules), seasonings (chili powder, cumin granules), etc.; but also can be used for non-food granules, including pharmaceutical granules (cold granules, Chinese herbal medicine decoction pieces granules), chemical granules (plastic particles, chemical fertilizer granules), feed granules and so on.

Conveyor / Feeder

PP bucket elevator The Z-type elevator transports materials by continuously moving buckets attached to a chain Z-shaped path. The buckets are loaded at the bottom horizontal section, elevated vertically, and then discharged at the top horizontal section by tipping or tilting, enabling efficient, enclosed conveyance of powdered and granular materials between multiple floors. Mainly used for conveying good fluidity of food, crops, such as: peanuts, soybeans, rice, candy, dried fruit and other food, but also used for hardware, chemical, pharmaceutical, granular material transportation. Z- bucket elevators allow feeding control in one or more positions and can be easily inter-operated with various types of feeding devices. All components have easy removal inspection covers and easy positioning inspection Windows. The bucket has a quick release mechanism for quick installation or removal of the bucket. All elevators are equipped with automatic zippers and built- in overload protection.

MOREFeatures and Advantages *Large conveying angle: By setting special push plates and skirts, it can effectively prevent materials from sliding down, enabling large-angle conveying. The lifting angle can reach 30-40 degrees or even higher. When space and product shape permit, it can replace continuous elevators. *Strong bearing capacity: With a robust structure, it can be used in heavy-duty conveying operations and is suitable for occasions with impact at loading and unloading points. It can convey large and sharp materials, and the weight of a single material (piece) being transported can reach 70-120kg. *Wide application range: There are various chain plate materials available, which can be selected according to different material characteristics and usage environments. For example, stainless steel is suitable for industries with high hygiene requirements such as food and pharmaceuticals; plastic-steel chain plates are resistant to acid, alkali, salt water, etc., and can be used in various harsh environments. *Stable and reliable operation: Adopting chain transmission, it runs smoothly with low noise and little wear. The chain has undergone heat treatment, featuring good wear resistance and a long service life. Meanwhile, the equipment has good sealing performance, which can prevent material leakage and ensure the cleanliness of the production environment. Application Fields *Food industry: Used for conveying fruits, poultry, canned drinks, cosmetics and cleaning products, etc., and can meet the needs of automatic conveying, grading and packaging. *Chemical industry: Suitable for conveying various chemical raw materials, such as granular and powdery materials, and can operate stably in corrosive environments. *Mining industry: Can be used to convey ores, slag, etc., and can adapt to the harsh working environment of mines, especially suitable for conveying large and sharp materials. *Other industries: Also widely used in electronics, electrical appliances, automobile, logistics and other industries for conveying various parts, packaged items, etc.

MORECore Functions 1.Adapting to steep angle conveying It solves the problem that ordinary flat conveyor belts are prone to material sliding and low conveying efficiency when the inclination angle is large. Through special structural designs (such as transverse partitions, corrugated ribs, etc.), it can stably convey bulk materials on steep slopes or even in vertical directions, effectively reducing the floor area occupied by the conveying line. 2.Wear resistance and corrosion resistance Polyurethane material itself has excellent wear resistance, tear resistance, and chemical corrosion resistance. It can adapt to the conveying of various materials (such as ores, coal, grain, chemical fertilizers, construction waste, etc.), and is especially suitable for working conditions where the conveyor belt is subject to significant wear or certain corrosiveness. 3.Low noise and environmental friendliness Compared with traditional rubber conveyor belts or metal conveying chains, PU material is relatively soft, resulting in lower noise during operation. Moreover, the material itself is non-toxic and easy to recycle, meeting environmental protection requirements. It is suitable for places with strict restrictions on noise and environment (such as food processing, urban waste treatment, etc.). 4.Flexible adaptation and efficient conveying It can be designed with different structures such as rib heights and partition spacings according to the characteristics of the conveyed materials (particle size, humidity, temperature, etc.) and angle requirements, realizing continuous and efficient material conveying and improving the automation level of the production process. Main Application Fields 1.Mining and metallurgy industry Conveying ore raw materials such as coal, iron ore, and limestone. It is widely used in steep slope conveying scenarios in underground mines or open-pit mines, reducing the difficulty of laying conveying lines due to terrain restrictions. 2.Building materials and chemical industry Used for conveying materials such as cement, sand, glass raw materials, chemical fertilizers, and plastic particles. Its corrosion resistance and wear resistance make it suitable for the special conveying needs of chemical raw materials. Agriculture and grain processing 3.Conveying agricultural products such as grains, beans, and feed. The environmental friendliness and low noise characteristics of PU materials make them suitable for scenarios in contact with food, and can prevent materials from sliding during inclined conveying in storage and processing links. 4.Construction waste and waste treatment In scenarios such as demolition sites, landfills, and waste recycling plants, it is used to convey mixed materials such as construction waste and domestic waste. The steep angle design can save site space and improve processing efficiency. 5.Port and logistics conveying In the bulk material loading and unloading links of ports and stations, it is used to convey materials (such as coal, grain) from ships and trucks to storage facilities through inclined lines, enhancing the continuity of loading and unloading operations.

MOREWorking Platform

Measuring Gauge

Features ❊ Individually adjust the amplitude during operation for easy operation. ❊ Multi-language operation, suitable for global markets. ❊ Controlled weighing and sequential material discharge prevents material blockage. ❊ Professional digital weighing module with high accuracy and excellent stability. ❊ Modular stepper motor drive for easy maintenance. Applicable Products It is suitable for quantitative weighing of common specifications of materials, such as candy/peanuts/snacks/potato chips/nuts/jelly/biscuits/bread/coffee beans/pet food/dry particles or hardware, vegetable salad/fruit salad/potatoes/onions and other vegetables/fruits with large target weight or large capacity.

MOREFeatures ❊ Individually adjust the amplitude during operation for easy operation. ❊ Multi-language operation, suitable for global markets. ❊ Controlled weighing and sequential material discharge prevents material blockage. ❊ Professional digital weighing module with high accuracy and excellent stability. ❊ Modular stepper motor drive for easy maintenance. Applicable Products It is suitable for quantitative weighing of common specifications of materials, such as candy/peanuts/snacks/potato chips/nuts/jelly/biscuits/bread/coffee beans/pet food/dry particles or hardware, vegetable salad/fruit salad/potatoes/onions and other vegetables/fruits with large target weight or large capacity.

MOREFeatures ❊ Individually adjustable amplitude during operation for easy operation. ❊ Multi-language operation, suitable for global markets. ❊ Controlled weighing and sequential material discharge prevents material blockage. ❊ Multi-outlet design allows for mixed and complementary mixing of multiple materials; the weight of the mixed material can be automatically compensated for by selecting a specific material. ❊ Professional digital weighing module with high accuracy and excellent stability. ❊ Modular stepper motor drive for easy maintenance. ❊ Can weigh 2-3 mixed materials, with a maximum speed of 140 bpm for a single material. Applicable Products Applicable Products: Suitable for quantitative weighing of small quantities of fluid granular materials, tea leaves, Chinese herbs, seeds, beans, coffee beans, chocolate beans, nuts, MSG, chicken bouillon, and other products.

MOREFeatures ❊ High-precision digital sensor enables high-speed, accurate weighing. ❊ Built-in help menu on the display for easy learning and operation. ❊ Independent screw adjustment during operation ensures more uniform feeding and improves mixing accuracy. ❊ Perfectly combining high precision and high speed, CPU calculations instantly select the optimal combination. ❊ Food contact parts are made of stainless steel, and aluminum parts feature a food-grade rust-proof coating. A stainless steel scale box is available as an option. Applicable Products Suitable for pickled vegetables, pre-prepared dishes, preserved vegetables, bamboo shoot shreds, spicy fish, preserved mustard greens, diced beans and radish, pickled cucumbers, casual meat products (boneless chicken feet, boneless duck feet, diced meat, braised pork, lamb tripe, fish skin, pig skin), casual soy products (spicy strips, vegetarian meat), mushrooms, bamboo shoot shreds, and other materials with poor flowability.

MOREFeatures ❊ Individually adjustable amplitude during operation for easy operation. ❊ Multi-language operation, suitable for global markets. ❊ Controlled weighing and sequential material discharge prevents material blockage. ❊ High-precision and high-standard sensors, with accuracy controlled to two decimal places. ❊ Professional digital weighing module, high accuracy and excellent stability. ❊ Modular stepper motor drive for easy maintenance. ❊ IP65-rated waterproof and dustproof design, suitable for operation in humid and dusty environments. Applicable Products Suitable for damaged items such as laundry detergent beads, quail eggs, dumplings, walnuts, and biscuits.

MOREPackaging Machine

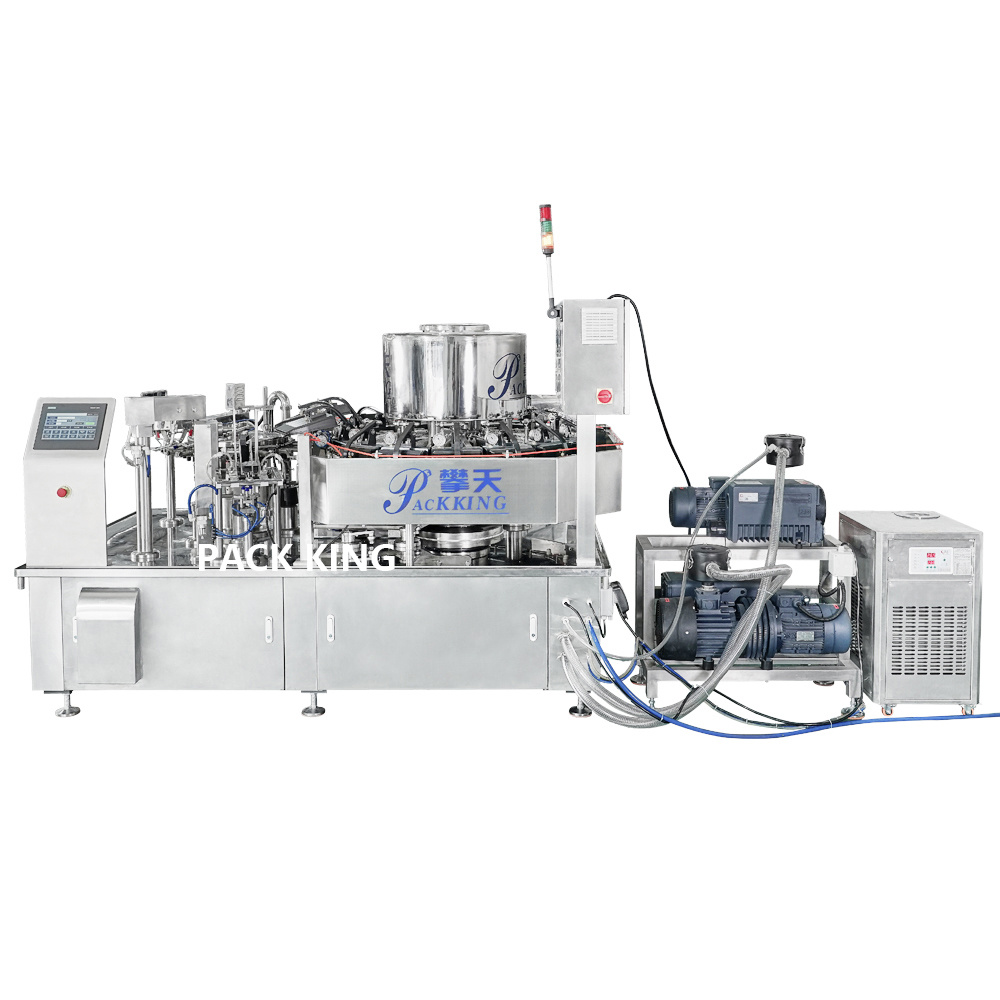

140-16ZK Vacuum premade packer

140-16ZK VACUUM PREMADE PACKER Packing speed:80-120 bags/min(speed is determined by product characteristics and filling weight) Bag Material:Aluminum foil bag,paper bag,nylon bag,etc. Packing bag specification:With:55~110mm Leng:60~190mm Total power:Main machine power≈6kw Air Consumption:0.8m³/min(compressed air supplied by user) Driving power:Standard three-phase 380V 50HZ Machine shape:2500mmx1500mmx1600mm(L*W*H) Main machine weight:3T Environment:Room temperature 10~40 degrees celsius,30~90% RH,no dew,no corrosive gases,no dust and other harsh environments.

MOREPT240-10ZK Vacuum bagging machine

Convenient operation, adopting high-end electrical control system, friendly man-machine interface, easy to operate. No downward material not sealing, unfilled bags can be recycled, no waste of bags. This equipment is suitable for all kinds of prefabricated bag products such as agricultural products, daily necessities, foodstuffs, spices, medicine, hardware, electronic products, agriculture and so on.

MORE